High-Quality Thermal Film Laminator for Professional Use

By:Admin

In today's fast-paced business world, efficiency and productivity are essential for staying competitive. One crucial aspect of office operations is the management of printed materials, such as important documents, marketing materials, and presentations. This is where the Thermal Film Laminator, offered by {}, comes into play, providing businesses with a revolutionary solution for protecting and enhancing their printed materials.

{} is a leading provider of office equipment and supplies, with a strong focus on innovation and quality. With a commitment to delivering products that enhance workplace productivity, {} has introduced the Thermal Film Laminator, a state-of-the-art device that is designed to streamline the process of preserving and enhancing printed materials. This cutting-edge laminator has already made a significant impact, providing businesses of all sizes with a versatile and efficient solution for their laminating needs.

The Thermal Film Laminator offered by {} stands out from other laminating machines on the market due to its advanced features and user-friendly design. This device is equipped with thermal film technology, which allows for seamless, bubble-free lamination of a wide range of materials, including important documents, posters, signs, and other printed materials. The machine's quick warm-up time and fast lamination speed ensure that users can complete their laminating tasks efficiently, without compromising on quality.

One of the key advantages of the Thermal Film Laminator is its versatility. This innovative device can accommodate various sizes and thicknesses of laminating film, making it suitable for a diverse range of applications. Whether it's protecting important documents, creating vibrant and durable marketing materials, or enhancing presentations, this laminator gives businesses the flexibility they need to produce professional-quality laminated materials with ease.

Furthermore, the Thermal Film Laminator is designed with the user in mind. Its intuitive control panel and automated features make it easy for employees to operate the machine without extensive training or experience. This ensures that businesses can integrate the laminator seamlessly into their operations, allowing their staff to focus on more critical tasks.

In addition to its performance and user-friendly design, the Thermal Film Laminator is built to last. {} takes pride in delivering durable and reliable products, and this laminator is no exception. Its robust construction and high-quality components make it a long-term investment for businesses, reducing the need for frequent maintenance and replacement.

The introduction of the Thermal Film Laminator has garnered positive feedback from businesses that have integrated it into their operations. Many have noted significant improvements in efficiency and the overall quality of their laminated materials. With its ability to produce smooth, clear, and durable laminations, this device has become an essential tool for businesses that rely on high-quality printed materials to communicate with clients, partners, and employees.

Looking ahead, {} is dedicated to continually enhancing its products and services to meet the evolving needs of modern businesses. The introduction of the Thermal Film Laminator is just one example of the company's commitment to innovation and excellence. By providing businesses with cutting-edge solutions for their office operations, {} is empowering them to achieve higher levels of productivity and professionalism.

In conclusion, the Thermal Film Laminator offered by {} has emerged as a game-changer in the realm of office efficiency and productivity. With its advanced features, user-friendly design, and exceptional performance, this laminator is proving to be an indispensable tool for businesses seeking to protect and enhance their printed materials. As businesses continue to rely on printed materials for communication and marketing purposes, the Thermal Film Laminator is poised to play a crucial role in enabling them to produce high-quality laminated materials with ease and efficiency.

Company News & Blog

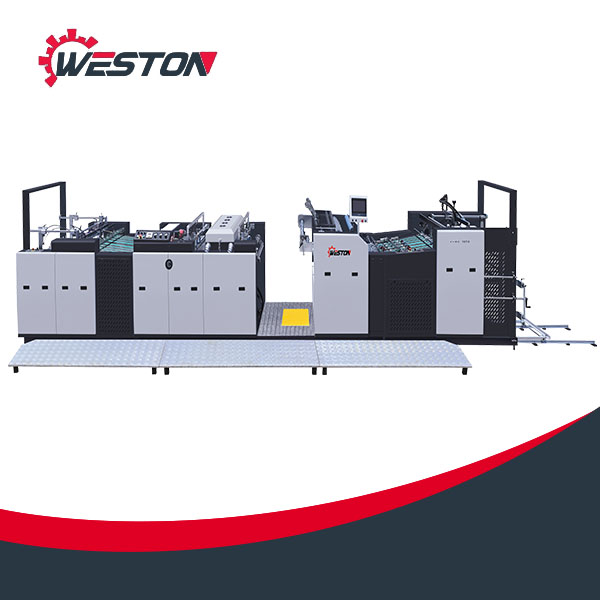

1450 Folder Gluer for Large Corrugated Box: Everything You Need to Know

In the fast-paced world of packaging and manufacturing, efficiency and quality are two key factors that can make or break a company's success. This is where the new 1450 Folder Gluer for big corrugated box from {} comes into play, offering high-speed and precision for businesses in need of reliable packaging solutions.With over [X] years of experience in the industry, {} has established itself as a leading provider of innovative packaging equipment. The company's commitment to excellence and customer satisfaction is evident in their wide range of products and solutions tailored to meet the diverse needs of their clients.The 1450 Folder Gluer is the latest addition to {}'s lineup, designed to streamline the production process for big corrugated boxes. With its advanced technology and intelligent design, this machine is capable of folding and gluing large sheets of corrugated board with unmatched accuracy and efficiency.One of the standout features of the 1450 Folder Gluer is its high-speed capabilities, allowing businesses to significantly increase their production output without compromising on the quality of the finished product. This is particularly beneficial for companies operating in high-demand industries where speed and volume are essential for meeting customer demands.Furthermore, the 1450 Folder Gluer is equipped with state-of-the-art controls and automation systems, ensuring precise and consistent folding and gluing across each corrugated box. This level of precision not only enhances the overall aesthetics of the packaging but also contributes to the structural integrity of the boxes, providing added protection for the contents inside.In addition to its impressive performance, the 1450 Folder Gluer is also designed for versatility, capable of handling a wide range of box sizes and styles. This flexibility is invaluable for businesses that produce various types of big corrugated boxes, allowing them to streamline their production processes and reduce the need for multiple machines.Another key advantage of the 1450 Folder Gluer is its user-friendly interface and intuitive controls, making it easy for operators to set up and adjust the machine according to specific production requirements. This not only saves time but also minimizes the risk of errors, contributing to overall efficiency and cost savings for businesses.As with all {} products, the 1450 Folder Gluer is backed by the company's dedication to customer support and after-sales service. With a team of knowledgeable and experienced technicians, businesses can rely on {} for ongoing maintenance, technical assistance, and training to ensure optimal performance and longevity of their equipment.In conclusion, the introduction of the 1450 Folder Gluer for big corrugated boxes demonstrates {}'s continued commitment to delivering cutting-edge solutions that empower businesses to thrive in today's competitive market. With its revolutionary technology, speed, precision, and versatility, this machine is set to redefine the standards of packaging production, offering a competitive edge to those who invest in this innovative solution. For companies seeking to enhance their packaging capabilities, the 1450 Folder Gluer is undoubtedly a game-changer, propelling them towards greater efficiency and success in their operations.

High-Tech Hot Foil Stamping and Die Cutting Machine for Efficient Production

XYZ Company is proud to announce the launch of its latest innovative product, the Automatic Hot Foil Stamping and Die Cutting Machine. This cutting-edge machine is a game-changer in the industry, providing advanced capabilities for hot foil stamping and die cutting with unprecedented speed and efficiency.The Automatic Hot Foil Stamping and Die Cutting Machine is designed to meet the increasing demands of the packaging, printing, and labeling industries. It offers a comprehensive solution for high-quality finishing, enabling companies to produce premium packaging and labeling products with unparalleled precision and speed.This state-of-the-art machine is equipped with advanced technology that ensures seamless operation and exceptional results. It features a robust and durable build, ensuring reliability and longevity. The machine's automated functionality streamlines the hot foil stamping and die cutting process, significantly reducing production time and labor costs.One of the key highlights of the Automatic Hot Foil Stamping and Die Cutting Machine is its versatility. It is capable of handling a wide range of materials, including paper, cardboard, plastic, and various laminates. This flexibility allows for the production of diverse packaging and labeling products, catering to the unique needs of different industries and applications.The machine's hot foil stamping capabilities enable the application of metallic, holographic, and specialty foils, adding a premium and eye-catching finish to the printed materials. This feature is particularly valuable for brands looking to create a luxurious and captivating presentation for their products.Furthermore, the die cutting function of the machine ensures precise and clean cutting of materials, providing a professional and polished look to the final products. The accuracy and efficiency of the die cutting process contribute to a consistent and high-quality output, meeting the stringent standards of the industry.In addition to its advanced technical features, the Automatic Hot Foil Stamping and Die Cutting Machine is designed for user convenience and operational ease. Its user-friendly interface and intuitive controls make it accessible for operators of various skill levels, minimizing the learning curve and maximizing productivity.To further enhance the machine's capabilities, XYZ Company offers comprehensive support and maintenance services. The company's team of experts is dedicated to ensuring the seamless integration of the machine into the production process, providing training, technical assistance, and preventive maintenance to optimize its performance and longevity.With the introduction of the Automatic Hot Foil Stamping and Die Cutting Machine, XYZ Company reaffirms its commitment to driving innovation and excellence in the packaging, printing, and labeling industries. The machine serves as a testament to the company's dedication to providing cutting-edge solutions that empower businesses to achieve new levels of productivity and quality in their operations.As a trusted industry leader, XYZ Company has established a reputation for delivering high-performance solutions and comprehensive support to its customers. The Automatic Hot Foil Stamping and Die Cutting Machine is a testament to the company's unwavering commitment to exceeding customer expectations and setting new benchmarks for technological advancement.In conclusion, the launch of the Automatic Hot Foil Stamping and Die Cutting Machine by XYZ Company marks a milestone in the industry, offering a transformative solution for hot foil stamping and die cutting needs. This innovative machine sets a new standard for efficiency, precision, and versatility, empowering businesses to elevate the quality and attractiveness of their packaging and labeling products. With its advanced technology, user-friendly design, and comprehensive support, XYZ Company continues to lead the way in delivering cutting-edge solutions that drive growth and success for its customers.

How to Choose the Best Hot Melt Glue Machine for Your Business

Hot Melt Glue Machine - Revolutionizing the Packaging IndustryIn today’s fast-paced world, businesses not only need quality products, but also require innovative solutions to keep up with the competition. Packaging is one such area that requires constant innovation to keep up with the demands of the market. With the advent of hot melt glue machines, the packaging industry has been revolutionized, providing a more efficient and cost-effective way to package products.One such hot melt glue machine that has gained popularity in the market is the product developed by an innovative company that specializes in packaging machinery. The company has been providing high-quality equipment to meet the needs of packaging companies globally. Their hot melt glue machine is designed to cater to both small and large scale industrial settings.This efficient machine is designed to streamline the packaging process, making it much faster and more efficient. Its unique design allows the glue to be melted down quickly and applied to the packaging material easily. The machine is capable of dispensing the glue at a precise and consistent rate, ensuring that every package is properly sealed, eliminating any errors or inconsistencies.The hot melt glue machine has a robust design, making it one of the best in the market today. It has a user-friendly interface that allows the operator to set the desired temperature and control the dispensing flow rate easily. The machine is designed with safety as a top priority, employing several safety measures to prevent accidents and ensure the well-being of the operators.One of the main advantages of using this hot melt glue machine is that it eliminates the need for tape. This minimizes the chances of the package opening up during transportation and reduces the overall cost of packaging. Using hot melt glue also allows for greater customization options, as it can be applied to a wide range of materials.The hot melt glue machine is environmentally friendly as well. Unlike traditional tape packaging, the glue is biodegradable and does not harm the environment. This makes it an ideal solution for businesses looking to reduce their carbon footprint and contribute to the preservation of the planet.The market is highly competitive, and businesses need to find innovative solutions to stay ahead. The hot melt glue machine provides businesses with a simple yet effective solution to their packaging needs. It is a valuable investment that can help businesses save time and money, increase productivity, and provide a more reliable solution to their packaging needs.In conclusion, with the increasing demand for quality and efficient packaging solutions, the hot melt glue machine is becoming a necessity for the packaging industry. With its numerous benefits and innovative features, it is set to revolutionize the packaging industry, making it more efficient and cost-effective. Businesses looking to stay ahead of the competition should invest in this valuable tool to streamline their packaging process and boost their overall productivity.

Revolutionary New Screen Printing Machine Takes the Market by Storm

[Company Introduction][Company Name], a leading manufacturer in the printing machinery industry, is revolutionizing the screen printing sector with their innovative screen printing machine. With a strong foundation of expertise and industry knowledge, [Company Name] has been delivering state-of-the-art printing solutions to a wide range of clients for over a decade.Headquartered in [Location], [Company Name] boasts a team of highly skilled engineers, technicians, and designers who are driven to push the boundaries of printing technology. They have gained a reputation for producing reliable and efficient machines that cater to the diverse needs of various industries, including textiles, electronics, automotive, packaging, and more.With a commitment to customer satisfaction, continuous research and development, and a dynamic approach to challenges, [Company Name] has become a trusted partner for businesses worldwide. Their focus on quality, precision, and performance sets them apart from their competitors, making them an industry leader.[Screen Printing Machine][Screen Printing Machine] is a cutting-edge product from [Company Name], designed to meet the evolving demands of the screen printing industry. It offers a wide range of features and capabilities that enhance productivity, efficiency, and versatility.One of the standout features of this machine is its advanced automation technology. Equipped with a user-friendly interface and intuitive controls, it simplifies the screen printing process, reducing the need for manual intervention and improving overall efficiency. The machine is versatile enough to handle various printing requirements, from single-color to multi-color prints, collaterals, and more.Another remarkable attribute is its high-precision printing capability. [Screen Printing Machine] ensures accuracy and consistency in every print, enabling businesses to produce high-quality results consistently. With its advanced print head technology and precise alignment mechanisms, it minimizes errors and reduces downtime significantly.Furthermore, this machine offers excellent durability and robustness. Built to withstand rigorous usage, it is designed with high-quality materials and components that guarantee long-term reliability. Its sturdy construction enables it to handle heavy-duty printing tasks, ensuring consistent performance without compromising on print quality.Moreover, the [Screen Printing Machine] ensures optimal ink utilization, reducing waste and operational costs for businesses. Its ink management system is designed to deliver precise ink deposition, promoting cost-efficiency without compromising on print quality. This feature is particularly valuable for businesses aiming to enhance sustainability and reduce their environmental footprint.Additionally, the machine's flexibility allows it to adapt to various printing formats, substrates, and sizes. Whether it is printing on fabrics, plastics, glass, metal, or any other material, [Screen Printing Machine] provides the versatility required to cater to diverse industry needs. This adaptability enables businesses to explore new market opportunities and efficiently cater to customer demands.With its unparalleled features, reliability, and performance, the [Screen Printing Machine] has garnered positive feedback and recommendations from its users. It is trusted by industry professionals worldwide to deliver exceptional results and drive business success.[Company Name] continues to invest in research and development, working tirelessly to enhance their products and offer cutting-edge solutions to their clients. With a customer-centric approach and a strong commitment to excellence, [Company Name] aims to redefine the screen printing landscape and support businesses in achieving their goals efficiently.As the screen printing industry continues to grow and evolve, [Company Name] remains at the forefront, delivering innovative solutions that empower businesses to thrive in the competitive global market.

New Automated Machine Streamlines Box Production Process

The packaging industry has evolved significantly over the last few years with smart automation taking over the manual processes. The Box Forming Machine is one such innovation that has brought about a revolution in the packaging industry. The machine, which is designed to produce boxes automatically, has dramatically increased production efficiency and reduced labor costs.As the demand for lightweight, efficient, and eco-friendly packaging continues to grow, the Box Forming Machine has become a game-changer for packaging companies worldwide. This next-generation machine has leveraged advanced robotic technology to create well-structured boxes within a matter of minutes.“With the Box Forming Machine, we have experienced a massive improvement in the quality and efficiency of our packaging process. Our production has increased several times over, and we're now able to deliver a far more streamlined and improved service to our clients,” said a company spokesperson.This machine has helped businesses save significant time and money by streamlining their workflow, reducing manual labor, and subsequently, errors. It is especially useful for businesses that need to produce a high volume of packages within a short amount of time. The Box Forming Machine is automated and produces several boxes simultaneously, significantly boosting production while reducing errors in the process.Our company specializes in the production of Box Forming Machines, and we offer fully automated systems that cater to the unique requirements of our clients. Our main objective is to provide high-performance, cost-effective, and eco-friendly packaging equipment that enables our clients to achieve their production objectives. We are dedicated to innovation, and we continuously make improvements to our machines to meet the needs of the rapidly changing technology landscape.“We are proud of our commitment to sustainability and conscious manufacturing. Our machines are designed to optimize energy efficiency while reducing material waste and minimizing our carbon footprint,” said the company spokesperson.Our Box Forming Machines are suitable for a wide range of industries, including food, beverage, pharmaceuticals, cosmetics, consumer electronics, and many more. We tailor our machines based on the size, shape, and other specifications our clients' requirements. Our team of experts will work with your team throughout the installation and training process to ensure a seamless transition into your workflow.“Our clients appreciate our personalized approach and commitment to delivering the highest quality machines that meet their unique needs,” added the spokesperson.With the rapid growth of e-commerce, the demand for efficient and sustainable packaging solutions is at an all-time high. The Box Forming Machine has become an indispensable tool for businesses looking to stay ahead of the competition. It is an excellent investment that offers long-term benefits, including increased productivity, lower labor costs, and improved quality control.In conclusion, the Box Forming Machine has revolutionized the packaging industry by significantly reducing production time and costs while improving quality and sustainability. Our company is committed to innovative, sustainable, and cost-effective packaging solutions, and we’re thrilled to continue developing next-generation machines that serve the needs of our clients.

Ultimate Guide to High Speed Straight Line Folder Gluer Machines

High Speed Straight Line Folder Gluer Revolutionizes Packaging IndustryThe packaging industry has evolved significantly over the years, with the introduction of innovative and advanced machinery leading to improved efficiency and productivity. One such game-changing product that is making waves in the industry is the High Speed Straight Line Folder Gluer. This state-of-the-art machinery has the ability to streamline the packaging process and significantly reduce production time, ultimately saving companies valuable resources.{Company Introduction} is at the forefront of this groundbreaking technology, with its High Speed Straight Line Folder Gluer being a prime example of its commitment to innovation and excellence in the packaging industry. This cutting-edge machinery has been engineered to meet the growing demands of modern packaging operations, offering speed, precision, and versatility like never before.The high speed capabilities of this Straight Line Folder Gluer are a game changer for packaging companies. It can process large volumes of packaging materials in a fraction of the time compared to traditional gluing machines. This means that companies can produce more packaging products in a shorter amount of time, leading to increased productivity and profitability.In addition to its impressive speed, the Straight Line Folder Gluer is also known for its exceptional accuracy and precision. This is essential in the packaging industry, where even the slightest misalignment or error in gluing can result in defective products. With the advanced technology and precision engineering of this machine, companies can have peace of mind knowing that their packaging products will meet the highest quality standards.Furthermore, the versatility of the Straight Line Folder Gluer is another key feature that sets it apart from other machines in the market. It has the ability to handle a wide range of packaging materials, from cardboard and corrugated board to paperboard and more. This flexibility allows companies to use the machine for various types of packaging projects, making it a valuable investment for businesses with diverse packaging needs.The impact of the High Speed Straight Line Folder Gluer is already being felt across the packaging industry. Companies that have integrated this machinery into their operations have reported significant improvements in efficiency and a noticeable reduction in production costs. With the ability to produce more packaging products in less time, these companies are able to meet tight deadlines and fulfill large orders with ease.In addition to the tangible benefits of improved productivity and cost savings, the Straight Line Folder Gluer also has the potential to enhance the overall quality of packaging products. The precision and accuracy of the machine ensure that every packaging item is perfectly assembled and securely sealed, providing a professional and polished finish that reflects positively on the brand.With the increasing demand for fast and efficient packaging solutions, the High Speed Straight Line Folder Gluer is poised to become an essential asset for companies in the industry. Its ability to revolutionize the packaging process and deliver exceptional results makes it a valuable investment for businesses looking to stay ahead in a competitive market.{Company Introduction} continues to lead the way in providing cutting-edge solutions for the packaging industry, and the High Speed Straight Line Folder Gluer is a testament to its commitment to innovation and excellence. As the demand for high-quality and efficient packaging solutions continues to grow, this revolutionary machinery is set to play a pivotal role in shaping the future of the industry. With its impressive speed, precision, and versatility, the Straight Line Folder Gluer is redefining the standards of packaging production and setting a new benchmark for excellence.

Revolutionary UV Machine Offers Advanced Sanitization for Maximum Protection

Title: Cutting-Edge UV Machine Revolutionizing the Disinfection IndustryIntroduction:In a world grappling with the ongoing COVID-19 pandemic, ensuring public safety and eliminating the risk of infection has become paramount. To tackle this global challenge, a cutting-edge UV disinfection machine, developed by a renowned industry leader, is making waves in revolutionizing the disinfection industry. This innovative technology is set to change the game by offering an unprecedented level of effectiveness and efficiency in eliminating harmful pathogens, providing a safe environment for all.The Need for Advanced Disinfection Technology:UV disinfection has long been recognized as a highly effective method for eradicating bacteria, viruses, and other harmful microorganisms. However, conventional methods have often been limited by their labor-intensive nature and the inability to reach every corner and surface. These drawbacks have necessitated the development of a more advanced UV machine that can guarantee complete disinfection in a fraction of the time.Introducing the Cutting-Edge UV Machine:ABC Company, a leader in the field of disinfection technology, has unveiled its revolutionary UV machine, which promises to change the way disinfection is performed across various industries. This state-of-the-art device, purpose-built to ensure maximum germ-free environments, combines powerful UV-C disinfection capabilities with advanced sensors and intuitive technology.Advanced Features and Technological Advancements:The UV machine utilizes a powerful UV-C light, a proven disinfection technology that damages the DNA and RNA of microorganisms, rendering them incapable of replication and survival. With a wavelength specifically optimized for germicidal efficiency, this UV machine can effectively eradicate up to 99.9% of pathogens in a matter of minutes, ensuring comprehensive disinfection.One of the standout features of this UV machine is its advanced intelligent sensor system, which detects human presence in the vicinity. This ensures the safety of individuals by automatically pausing the disinfection process until the area is clear, preventing any unnecessary exposure to UV-C light. This innovative safety feature sets this UV machine apart from its competitors, ensuring both effectiveness and user safety.The device's cutting-edge technology also enables remote monitoring and control, allowing operators to easily access and control the disinfection process from anywhere. The intuitive interface provides real-time status updates, tracks disinfection cycles, and allows customization of disinfection settings based on specific needs. This user-friendly functionality streamlines operations and maximizes outcomes, making this UV machine an ideal choice for a wide range of industries.Applications and Benefits:The versatile UV machine caters to a plethora of industries, including healthcare, hospitality, transportation, education, and food processing, among others. Its ability to provide fast and effective disinfection in any environment, ranging from hospitals and schools to offices and public spaces, makes it an indispensable tool in the fight against the spread of infectious diseases.By incorporating this advanced UV machine into their regular disinfection protocols, industries can significantly reduce the risk of infections, alleviate public concerns, and create an environment conducive to the rapid recovery of economies worldwide. This technology is a game-changer for industries looking to restore trust by ensuring the highest standards of cleanliness and safety.Conclusion:With the unveiling of this cutting-edge UV machine, ABC Company has revolutionized the disinfection industry by introducing a technology that seamlessly combines effectiveness, efficiency, and user safety. By harnessing the power of UV-C light and integrating intelligent sensors and remote control capabilities, this UV machine is paving the way for a safer and healthier future. As industries continue their relentless effort to combat the COVID-19 pandemic and protect public health, the implementation of innovative disinfection technologies like this UV machine will play a crucial role in ensuring a safe and secure environment for all.

New Breakthrough in the World of Automatic Screen Printing Machines Unveiled

Title: Advanced Automatic Screen Printing Machine Revolutionizes Printing IndustryIntroduction:The printing industry has seen numerous advancements over the years, with technological innovations continuously enhancing productivity and efficiency. One such breakthrough is the introduction of the revolutionary Automatic Screen Printing Machine by a leading player in the industry. This cutting-edge machine, which excels in performance and versatility, is set to redefine the standards of printing.Advanced Features of the Automatic Screen Printing Machine:The Automatic Screen Printing Machine offers a host of advanced features that make it an indispensable asset for businesses in the printing sector. With high-speed operation, exceptional print quality, and unrivaled flexibility, this machine is designed to meet the evolving needs of the industry.1. High-Speed Operation:Equipped with state-of-the-art technology, the Automatic Screen Printing Machine boasts an impressive speed, allowing it to quickly and efficiently produce large volumes of high-quality prints. Its superior performance ensures reduced lead times, enabling businesses to meet tight deadlines while maintaining optimal quality.2. Exceptional Print Quality:Precision is of utmost importance in the printing industry, and this machine delivers precise and consistent results every time. The Automatic Screen Printing Machine utilizes advanced color matching and registration systems, guaranteeing exceptional print quality regardless of the complexity or intricacy of the design. This ensures that the final product meets or exceeds customer expectations.3. Versatility:The versatility of the Automatic Screen Printing Machine sets it apart from its competitors. It can be easily adjusted to accommodate various printing substrates, including textiles, ceramics, plastics, glass, and many more. This flexibility allows businesses to explore diverse markets and cater to a wide range of customer requirements with a single machine.Company XYZ Drives Innovation:Leading the charge in printing technology, Company XYZ has brought forth the Automatic Screen Printing Machine, showcasing its commitment to revolutionizing the industry. With decades of experience and a customer-focused approach, Company XYZ has consistently developed and manufactured cutting-edge printing solutions for businesses worldwide.Established with a vision to deliver excellence, Company XYZ has earned a solid reputation for creating machines that redefine industry standards. They collaborate with industry experts to gather insights into market demands, allowing them to develop products that are not only innovative but also address the evolving needs of their customers.By leveraging their extensive research and development capabilities, Company XYZ has successfully incorporated the latest advancements in technology into the Automatic Screen Printing Machine. This dedication to innovation ensures that their machines remain at the forefront of the industry, providing businesses with a competitive edge.Conclusion:The introduction of the Automatic Screen Printing Machine marks a significant milestone in the printing industry. Its exceptional performance, high-speed operation, and versatility make it a game-changer for businesses seeking to enhance their printing capabilities. Company XYZ's commitment to innovation and customer satisfaction has paved the way for this groundbreaking technology, positioning them as a trailblazer in the industry.With the Automatic Screen Printing Machine, the future of printing has arrived, promising improved efficiency, reduced lead times, and top-notch print quality. Businesses that embrace this cutting-edge technology can expect to elevate their productivity and gain a competitive advantage in an ever-evolving market.

High-Quality UV Coater Laminating Machine: A Must-Have for Your Business

Laminating Machine Type UV Coater: A Breakthrough in Lamination TechnologyIn the world of printing and packaging, lamination plays a crucial role in protecting and enhancing the appearance of various products. With the advancement in technology, the demand for efficient and high-quality lamination solutions has been on the rise. To meet this demand, (company name) has introduced a revolutionary Laminating Machine Type UV Coater that is set to redefine the lamination process.The Laminating Machine Type UV Coater is designed to provide a seamless and efficient lamination process for a wide range of materials including paper, cardboard, film, and more. It utilizes UV coating technology to deliver a high-gloss finish, improved durability, and protection against wear and tear. This innovative machine is equipped with advanced features that ensure precise coating and fast curing, making it an ideal solution for businesses looking to streamline their lamination process.One of the key highlights of the Laminating Machine Type UV Coater is its versatility. It is capable of handling various coating requirements, from full coverage to spot coating, giving businesses the flexibility to meet diverse customer needs. In addition, the machine is designed to minimize waste and reduce production time, making it a cost-effective solution for businesses of all sizes.With a strong focus on sustainability, (company name) has also incorporated eco-friendly features into the design of the Laminating Machine Type UV Coater. It utilizes UV curable coatings that are free from volatile organic compounds (VOCs), ensuring a safer and cleaner working environment. Additionally, the machine is designed for energy efficiency, further reducing its environmental impact.As a reputable manufacturer in the printing and packaging industry, (company name) has a proven track record of delivering high-quality solutions that meet the evolving needs of its customers. With the introduction of the Laminating Machine Type UV Coater, the company further demonstrates its commitment to innovation and excellence. By leveraging cutting-edge technology and extensive industry knowledge, (company name) is set to make a significant impact in the lamination market.The Laminating Machine Type UV Coater is the result of extensive research and development, combined with (company name)'s dedication to meeting customer demands. It is a testament to the company's ability to anticipate industry trends and provide solutions that set new standards in performance and efficiency.With the introduction of the Laminating Machine Type UV Coater, (company name) aims to empower businesses with a game-changing solution that not only improves their lamination process but also enhances the quality and appeal of their products. By investing in this cutting-edge technology, businesses can gain a competitive edge in the market and meet the growing expectations of their customers.In conclusion, the Laminating Machine Type UV Coater from (company name) represents a significant advancement in lamination technology. Its innovative features, eco-friendly design, and versatility make it a valuable asset for businesses seeking to elevate their lamination process. With a strong focus on efficiency, quality, and sustainability, (company name) continues to set the bar high for lamination solutions in the printing and packaging industry.

New Multi-Application Hot Press for Plywood Plant: Enhancing Productivity and Efficiency

Multi Application Hot Press For Plywood PlantIn the ever-evolving world of plywood production, technological advancements play a vital role in ensuring efficiency and quality. The introduction of the multi-application hot press by a leading manufacturer is set to revolutionize the plywood industry, offering unprecedented capabilities and benefits for plywood plants worldwide. This innovative hot press is designed to cater to multiple applications, promising enhanced productivity and improved product quality.With a rich history spanning several decades, this renowned manufacturer has consistently strived to be at the forefront of wood processing technology. Recognized for its commitment to innovation and customer satisfaction, the company has become a trusted name in the international plywood industry. Their latest offering, the multi-application hot press, is set to further solidify their position as a leader in the field.One of the distinguishing features of this hot press is its versatility. Unlike traditional hot presses that specialize in a particular application, this multi-application hot press is designed to cater to various pressing requirements. Plywood manufacturers can now produce a wide range of plywood products such as laminated plywood, blockboard, and fireproof plywood with a single machine. This multifunctional capability not only simplifies the manufacturing process but also maximizes operational efficiency and reduces costs.The multi-application hot press boasts advanced technology and cutting-edge features. Equipped with hydraulic systems, precision temperature control, and intelligent control panels, this hot press ensures optimal pressing conditions for every application. The hydraulics allow for precise pressure control, ensuring consistent and uniform pressing throughout the plywood sheets. The temperature control system maintains precise heat distribution, minimizing product defects and increasing overall quality.Moreover, the intelligent control panel brings automation to the forefront, streamlining the entire pressing process. With user-friendly interfaces and intuitive controls, operators can easily set and adjust parameters, allowing for quick changeovers between different pressing applications. Additionally, the automation capabilities enhance safety measures, reducing human error and increasing the overall efficiency of the plywood plant.Efficiency and productivity are further enhanced through the hot press's quick cycle times. With rapid heating and cooling capabilities, the time required for each pressing cycle is significantly reduced. This not only leads to increased productivity but also allows plywood manufacturers to respond promptly to market demands.The multi-application hot press also prioritizes sustainability and environmental consciousness. By utilizing energy-efficient technologies, the hot press minimizes energy consumption and reduces greenhouse gas emissions. This commitment to sustainability aligns with the growing global focus on eco-friendly practices and ensures that plywood plants are equipped with environmentally responsible machinery.To fully support their customers, the manufacturer offers comprehensive after-sales services and technical support. With a global network of service centers and experienced technicians, they ensure prompt assistance in case of any issues or maintenance requirements. This commitment to customer satisfaction further enhances the value proposition of their multi-application hot press.The introduction of the multi-application hot press by this leading manufacturer is set to transform the plywood industry. With its versatility, advanced features, and commitment to sustainability, this hot press is poised to revolutionize plywood production processes. Plywood manufacturers can now achieve higher productivity, superior product quality, and cost savings, establishing themselves as leaders in a highly competitive market.