| Model | YFMB-950B | YFMB-1100B |

| Max Paper Size | 920mm | 1040mm |

| Paper Thickness | 100-500g/m2 | 100-500g/m2 |

| Laminating Speed | 0-30m/min | 0-30m/min |

| Power | 15kw | 18kw |

| Total Weight | 1900kg | 2100kg |

| Overall Dimensions | 4500x1800x1500mm | 4800x1950x1500mm |

| Heating Roller Diameter | 320mm | 320mm |

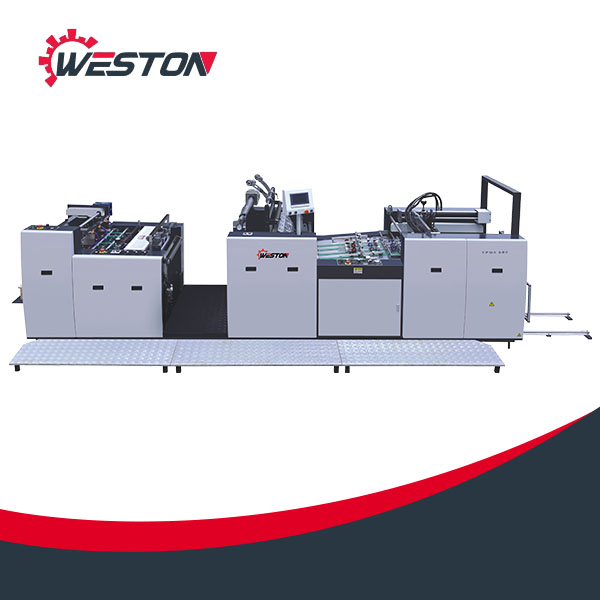

●YFMB-950B series thermal laminator is the most advanced manual feeding laminating equipment. This machine is with the characters of high-automation, easy-operation, safety and stability. It can widely adopt in carton packaging, label making and digital printing product. It’s the good choice for large and medium sized printing house1100 model package size: 2250*2000*1750mm 950 model package size: 2250*1800*1650mmb)Pneumatic film unwinding system positions film.roll more accurately, and makes the loading and unloading of film roll and film unwinding tension much more convenient.Double sets of serrated perforating wheels provide different choices for different specifications of sheets and film.

●YFMB-950B series thermal laminator is the most advanced manual feeding laminating equipment. This machine is with the characters of high-automation, easy-operation, safety and stability. It can widely adopt in carton packaging, label making and digital printing product. It’s the good choice for large and medium sized printing house1100 model package size: 2250*2000*1750mm 950 model package size: 2250*1800*1650mmb)Pneumatic film unwinding system positions film.roll more accurately, and makes the loading and unloading of film roll and film unwinding tension much more convenient.Double sets of serrated perforating wheels provide different choices for different specifications of sheets and film.

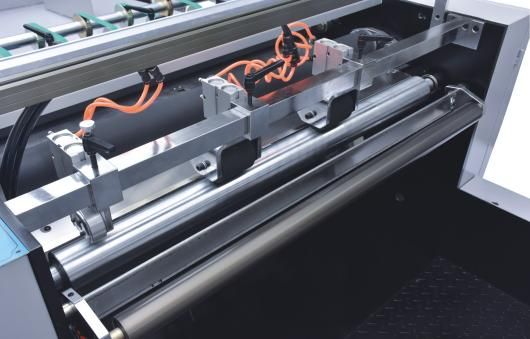

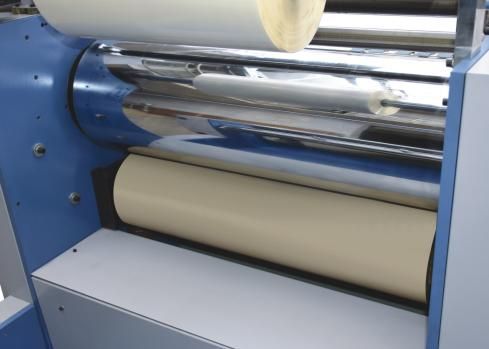

g)Air expansion shaft releases film, and positioning accuracy,also makes the loading and unloading of film roll more convenient.d)Corrugating delivery system ensure paper collection more regular. Anti-curling device: when paper going through anti-curl device, the laminated paper shall be leveled at once and wont curve again after cutting c)Perfected traction adjusting system makes traction adjustment more convenient and efficient.

g)Air expansion shaft releases film, and positioning accuracy,also makes the loading and unloading of film roll more convenient.d)Corrugating delivery system ensure paper collection more regular. Anti-curling device: when paper going through anti-curl device, the laminated paper shall be leveled at once and wont curve again after cutting c)Perfected traction adjusting system makes traction adjustment more convenient and efficient.  e)Hydraulic pressuring system provides big and steady pressure to guarantee good laminating quality.f)Pneumatic cutting system realizes automatic paper cut as long as the operator inputs the workable paper size on the text screen.

e)Hydraulic pressuring system provides big and steady pressure to guarantee good laminating quality.f)Pneumatic cutting system realizes automatic paper cut as long as the operator inputs the workable paper size on the text screen.

| NO. | Name | MODEL | QTY | REMARKS |

| 1 | PLC | 40MT | 1 | Inovance |

| 2 | touch screen | 6070T | 1 | WEILUN |

| 3 | Servo drive | IS5-9S2R8/400W | 1 | Inovance |

| 4 | frequency changer | 2.2KW | 1 | PNEUMATIC |

| frequency changer | 4KW | 1 | HYDRAULIC PREASURE | |

| 5 | miniature circuit breaker | DZ60-47/C32A | 1 | SIEMENS |

| 6 | miniature circuit breaker | DZ60-47/C10 | 2 | SIEMENS |

| 7 | alternating current contactor | 1210/220V | 6 | SIEMENS |

| 8 | alternating current contactor | 3210/220V | 1 | SIEMENS |

| 9 | intermediate relay | MY2N-J | 9 | OMRON |

| 10 | Solid state contactor | J25S25 | 2 | CHINA |

| 11 | Voltage heating module | 3PH60DA-H | 1 | WUXI |

| 12 | limit switch | YBLX-ME/8108 | 2 | SIEMENS |

| 13 | Pressure limit switch | ME-8111 | 1 | SIEMENS |

| 14 | Reflection type photoelectric switch | HE18-R2N/24V | 1 | OMRON |

| 15 | Square photoelectric switch type | E3Z | 1 | OMRON |

| 16 | photoelectric switch | DS30 | 1 | OMRON |

| 17 | proximity switch | BB-U202N/24V | 1 | OMRON |

| 18 | pilot lamp | XB2 | 1 | SIEMENS |

| 19 | Transfer switch | ZB2-BDZC | 4 | SIEMENS |

| 20 | stop switch | BS54C | 3 | SIEMENS |

| 21 | button switch | ZB2(Green、White、Red) | 2(Green)+1(white)+1(red) | SIEMENS |

| 22 | encoder | E6BZ-CW26C/1000R/24V | 1 | OMRON |

| 23 | Power Module | S-35-24 | 1 | TAIWANG |

| 24 | temperature-sensing wire | 1-model | 1 | OMRON |

| 25 | thermograph | MXTG-6501 | 1 | OMRON |

| 26 | Switch contact | Normal open:ZBS-BZ101 | 10 | OMRON |