Welcome to Weston

WESTON is a distinguished company specializing in the export of printing and packaging equipment. We are renowned as one of the foremost global providers of exceptional substrate processing, printing, and conversion equipment, along with top-notch services catered to the label, flexible packaging, folding carton, and corrugated industries. Our expertise extends beyond equipment sales, as we proudly offer comprehensive consultation services to assist our valued clients.

Read More...Why Choose Us

Hot Products

Automatic High Speed V Bottom Food Paper Bag Making Machine

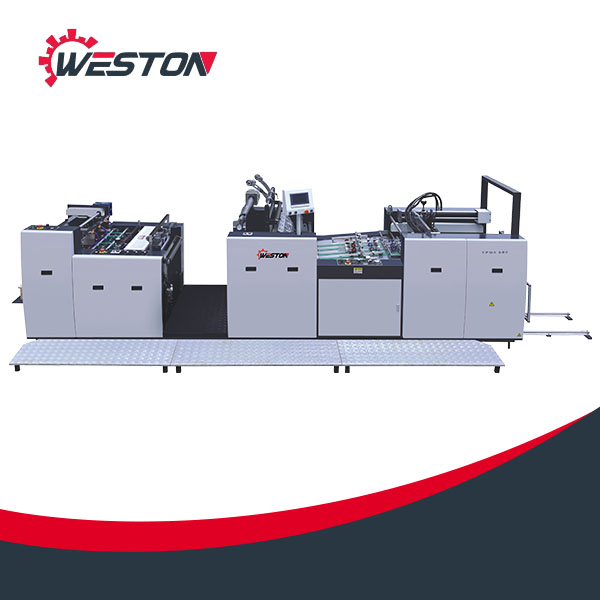

YFMB-540 Oil Heating high quality hydraulic pressure Semi auto thermal film paper laminating machine for Leaflets

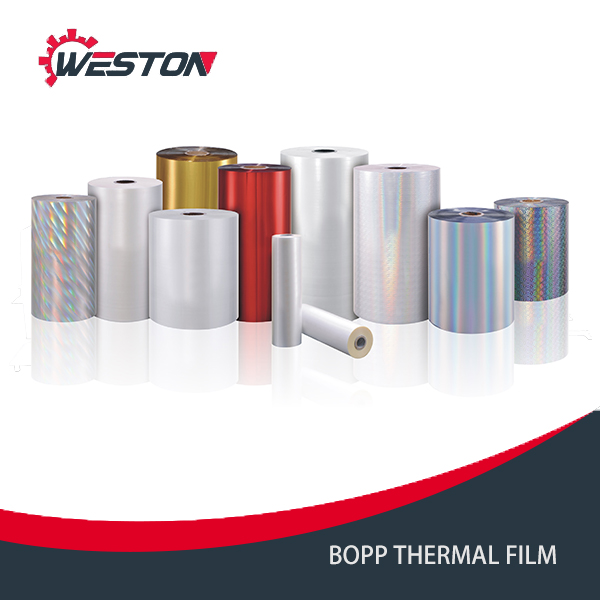

BOPP PET Color Hologram/Laser Thermal Lamination Film for Paper

YFMB-950B 1100B Semi-automatic bopp plastic film Laminating Machine With cutter big pressure printed paper board hot laminator

YFMA-590/800A Automatic Thermal Laminating Machine with embossing feature for photo book

SGUV-660 /760 Manual Whole UV Gloss Anti Scratch Varnish Machine Water base Coating Machine for Paper and Plastic Film Glazing Machine

WST-1300 1450 1650 H Semi Automatic Laminator Flute Laminating Machine for Cardboard and Corrugated Board

WST-BK800/1150 Fully automatic Paper cardboard laminating

WST-1450H High speed automatic corrugated paper cardboard sheet flute Laminating Machine with Flip Flop

WESTON ZFM-700 900 Semi-Automatic Album Cover Making Machine Cellphone cover maker Case Maker Case making machine

Cooperative Company Reviews

Company News & Blog

High-Tech Hot Foil Stamping and Die Cutting Machine for Efficient Production

XYZ Company is proud to announce the launch of its latest innovative product, the Automatic Hot Foil Stamping and Die Cutting Machine. This cutting-edge machine is a game-changer in the industry, providing advanced capabilities for hot foil stamping and die cutting with unprecedented speed and efficiency.The Automatic Hot Foil Stamping and Die Cutting Machine is designed to meet the increasing demands of the packaging, printing, and labeling industries. It offers a comprehensive solution for high-quality finishing, enabling companies to produce premium packaging and labeling products with unparalleled precision and speed.This state-of-the-art machine is equipped with advanced technology that ensures seamless operation and exceptional results. It features a robust and durable build, ensuring reliability and longevity. The machine's automated functionality streamlines the hot foil stamping and die cutting process, significantly reducing production time and labor costs.One of the key highlights of the Automatic Hot Foil Stamping and Die Cutting Machine is its versatility. It is capable of handling a wide range of materials, including paper, cardboard, plastic, and various laminates. This flexibility allows for the production of diverse packaging and labeling products, catering to the unique needs of different industries and applications.The machine's hot foil stamping capabilities enable the application of metallic, holographic, and specialty foils, adding a premium and eye-catching finish to the printed materials. This feature is particularly valuable for brands looking to create a luxurious and captivating presentation for their products.Furthermore, the die cutting function of the machine ensures precise and clean cutting of materials, providing a professional and polished look to the final products. The accuracy and efficiency of the die cutting process contribute to a consistent and high-quality output, meeting the stringent standards of the industry.In addition to its advanced technical features, the Automatic Hot Foil Stamping and Die Cutting Machine is designed for user convenience and operational ease. Its user-friendly interface and intuitive controls make it accessible for operators of various skill levels, minimizing the learning curve and maximizing productivity.To further enhance the machine's capabilities, XYZ Company offers comprehensive support and maintenance services. The company's team of experts is dedicated to ensuring the seamless integration of the machine into the production process, providing training, technical assistance, and preventive maintenance to optimize its performance and longevity.With the introduction of the Automatic Hot Foil Stamping and Die Cutting Machine, XYZ Company reaffirms its commitment to driving innovation and excellence in the packaging, printing, and labeling industries. The machine serves as a testament to the company's dedication to providing cutting-edge solutions that empower businesses to achieve new levels of productivity and quality in their operations.As a trusted industry leader, XYZ Company has established a reputation for delivering high-performance solutions and comprehensive support to its customers. The Automatic Hot Foil Stamping and Die Cutting Machine is a testament to the company's unwavering commitment to exceeding customer expectations and setting new benchmarks for technological advancement.In conclusion, the launch of the Automatic Hot Foil Stamping and Die Cutting Machine by XYZ Company marks a milestone in the industry, offering a transformative solution for hot foil stamping and die cutting needs. This innovative machine sets a new standard for efficiency, precision, and versatility, empowering businesses to elevate the quality and attractiveness of their packaging and labeling products. With its advanced technology, user-friendly design, and comprehensive support, XYZ Company continues to lead the way in delivering cutting-edge solutions that drive growth and success for its customers.

Efficient and Time-saving Cold Laminating Machine for All Your Needs

Title: Revolutionary Automatic Cold Laminating Machine Unveiled by Cutting-Edge Technology CompanyIntroduction: In the rapidly evolving landscape of printing and laminating technology, one company is set to redefine the industry with the launch of their ground-breaking Automatic Cold Laminating Machine. Introducing cutting-edge features and innovative design, this state-of-the-art machine promises to streamline and enhance the laminating process like never before. Developed by a renowned technology company with a reputation for excellence, this new addition to their product line is set to revolutionize the laminating industry.[Company Name], a leading player in technological advancements, is proud to introduce the latest addition to their product range, the Automatic Cold Laminating Machine. Exemplifying their commitment to providing innovative solutions, this machine is poised to set new standards in efficiency, ease-of-use, and quality.With an emphasis on cutting-edge design and incorporating advanced automation features, this Automatic Cold Laminating Machine is engineered to deliver consistent, professional-grade laminating results across a wide range of applications. Its sleek and compact design ensures it can fit seamlessly into any printing or design environment, saving precious workstation space.One of the standout features of this machine is its automatic feeding system, which significantly reduces the need for manual intervention. This game-changing feature eliminates the laborious task of manually feeding each document or sheet, allowing users to save time and increase productivity. By automating the feeding process, the Automatic Cold Laminating Machine ensures a seamless and uninterrupted laminating experience, with fewer errors and enhanced efficiency.Furthermore, the Intelligent Control Panel integrates an intuitive interface, providing easy navigation through various options and settings. The panel allows users to adjust the laminating speed, temperature, and pressure, catering to specific requirements for different materials. The machine's intelligent sensors ensure precise control, resulting in uniform laminating quality across every project.Equipped with state-of-the-art technologies, the Automatic Cold Laminating Machine guarantees outstanding laminating performance on various materials, including photographs, posters, documents, and more. Its cold lamination capability eliminates the risk of heat damage, making it the ideal choice for sensitive materials such as heat-sensitive inks or photos.The innovative design of this machine also focuses on energy efficiency, incorporating features that help reduce power consumption without compromising performance. This environmentally conscious approach aligns with [Company Name]'s commitment to sustainable manufacturing practices and responsible technology.Adding to its versatility, the Automatic Cold Laminating Machine boasts compatibility with various laminating film thicknesses and widths. This allows users the freedom to choose the perfect film specifications according to their desired application, ensuring outstanding results on every project.As professionals in the industry adapt to changing market needs, the launch of this Automatic Cold Laminating Machine by [Company Name] is set to transform the laminating process. By investing in cutting-edge technology and meticulously engineered features, the company reiterates its dedication to meeting customer demands for efficient and high-quality laminating solutions.In conclusion, the introduction of the Automatic Cold Laminating Machine offers a glimpse into the future of laminating technology. With unparalleled automation, user-friendly interfaces, and exceptional performance, this machine is poised to modify the way professionals tackle laminating tasks. [Company Name]'s commitment to innovation ensures that this product will set new industry standards, revolutionizing the laminating experience for businesses and individuals alike.

Revolutionizing the Film Industry: Discover the Must-Have Dry Film Machine

Title: Cutting-Edge Dry Film Machine Revolutionizes Production ProcessIntroduction:In today's rapidly evolving manufacturing industry, technological advancements play a crucial role in enhancing productivity and efficiency. One such breakthrough comes in the form of a state-of-the-art Dry Film Machine, designed and developed by an innovative company. This groundbreaking equipment revolutionizes the production process, offering unparalleled accuracy and reliability. By combining cutting-edge technology with meticulous craftsmanship, the Dry Film Machine promises to transform industries and set new benchmarks for excellence.Section 1: Understanding the Dry Film MachineThe Dry Film Machine is a sophisticated device that specializes in applying dry film solder masks onto printed circuit boards (PCBs). This automated system streamlines the production process, reducing manual labor and ensuring impeccable quality control. By utilizing advanced robotics and precise digital controls, the Dry Film Machine provides consistent and uniform applications, resulting in optimally functional PCBs.Section 2: Features and Benefitsa) High Precision: The Dry Film Machine boasts exceptional precision, strategically positioning dry film solder masks onto PCBs with micron-level accuracy. This precision eliminates the risk of misalignments, improving overall performance and reliability.b) Increased Efficiency: Through its automated processes, the Dry Film Machine significantly reduces production time. With faster and more precise application capabilities, manufacturers can streamline their processes, swiftly meeting market demands.c) Cost-Effective: By reducing manual intervention in the solder mask application process, the Dry Film Machine curtails labor costs, while minimizing material waste and enhancing yield rates.d) Reliability: The Dry Film Machine guarantees uniform coverage, ensuring reliable, consistent performance of PCBs.Section 3: How It WorksThe Dry Film Machine utilizes advanced technologies to achieve optimal results. An integrated imaging system is equipped with high-resolution cameras, enabling precise alignment. Additionally, the machine's software analyzes and adjusts the application parameters based on the characteristics of each PCB, ensuring accurate and repeatable results.Section 4: Industry ApplicationsThe Dry Film Machine holds immense potential across various industries, including:a) Electronics Manufacturing: The production of intricate PCBs requires precise solder mask application, making the Dry Film Machine an indispensable asset for electronics manufacturers.b) Automotive: The automotive industry can leverage the Dry Film Machine to enhance the performance, durability, and longevity of PCBs used in vehicle electronics systems.c) Aerospace: The aerospace sector demands stringent quality control and maximum reliability. The Dry Film Machine facilitates the production of high-quality PCBs, meeting the industry’s exacting requirements.d) Telecommunications: The rapid growth of the telecommunications market necessitates efficient and reliable PCB production. The Dry Film Machine's ability to consistently deliver high-quality solder masks aligns perfectly with this sector's requirements.Section 5: Company Introduction{}, the innovators behind the Dry Film Machine, are renowned for their commitment to excellence and market-leading technology. With years of experience in developing advanced machinery, they continue to redefine industry standards. Committed to research and development, their team of skilled engineers and scientists prioritize customer satisfaction, delivering tailor-made solutions that meet specific industry needs.Conclusion:The Dry Film Machine revolutionizes the production process, elevating industry standards by ensuring precise, efficient, and reliable solder mask application. With its cutting-edge technology and unwavering commitment to excellence, it addresses the needs of various sectors, ranging from electronics manufacturing to aerospace. As we move towards a future shaped by automation and advanced manufacturing techniques, the Dry Film Machine stands as a testament to the possibilities that lie ahead, offering increased efficiency, enhanced productivity, and consistent quality.

Unlocking the Power of Screen Printing: A Comprehensive Guide

A leading screen printer in the UK, with a reputation for quality and excellence, is celebrating its latest business milestone as it continues to grow and expand its operations.The company, which specialises in high-quality screen printing and embroidery services for a wide range of clients across the UK, has just announced the purchase of a brand-new state-of-the-art printing machine that will enable them to handle even larger orders with greater speed and efficiency.The growth of the business reflects a trend towards increased demand for customised apparel, as more and more companies seek to differentiate their branding and enhance their marketing efforts with branded merchandise.Established over a decade ago, the company has built a reputation for quality and reliability, thanks to its skilled team of expert technicians who are all highly experienced in the screen printing process.Using the latest technology and top-quality materials, the screen printing and embroidery services provided by the company allow clients to create customised designs that are tailored to their exact specifications.With a commitment to quality and excellence that is second to none, the company has established itself as a leader in the field of screen printing and embroidery services. Their ability to produce high-quality, customised designs at scale has seen them gain a loyal following of clients across a diverse range of industries, including fashion, sports, retail, and corporate branding.The purchase of the new state-of-the-art printing machine is part of the company's ongoing commitment to investing in the latest technology and equipment, ensuring that they remain at the forefront of their industry and can continue to offer their customers the very best service and quality.Commenting on the purchase of the new machine, the company's director said, "We are thrilled to be able to add this fantastic new piece of equipment to our arsenal. It will enable us to handle even larger orders with speed and efficiency, while still maintaining the high quality and attention to detail that our clients have come to expect from us."The director went on to add, "At our core, we are a company that is committed to providing the very best screen printing and embroidery services to our clients. We believe that this investment in the latest technology and equipment will help us to grow and expand our operations, while also maintaining our reputation for quality and excellence."With the new printer now installed and ready to use, the company is looking forward to expanding its customer base and taking on even bigger and more challenging orders. Whether it is customised t-shirts, hats, or even personalised apparel and merchandise, the team at this leading screen printer is well-equipped to deliver the very best in quality and value for its customers. So, if you are looking for high-quality, customised screen printing or embroidery services, look no further than this leading UK screen printer – a company that is committed to excellence, customer satisfaction, and continuous improvement.

1450 Folder Gluer for Large Corrugated Box: Everything You Need to Know

In the fast-paced world of packaging and manufacturing, efficiency and quality are two key factors that can make or break a company's success. This is where the new 1450 Folder Gluer for big corrugated box from {} comes into play, offering high-speed and precision for businesses in need of reliable packaging solutions.With over [X] years of experience in the industry, {} has established itself as a leading provider of innovative packaging equipment. The company's commitment to excellence and customer satisfaction is evident in their wide range of products and solutions tailored to meet the diverse needs of their clients.The 1450 Folder Gluer is the latest addition to {}'s lineup, designed to streamline the production process for big corrugated boxes. With its advanced technology and intelligent design, this machine is capable of folding and gluing large sheets of corrugated board with unmatched accuracy and efficiency.One of the standout features of the 1450 Folder Gluer is its high-speed capabilities, allowing businesses to significantly increase their production output without compromising on the quality of the finished product. This is particularly beneficial for companies operating in high-demand industries where speed and volume are essential for meeting customer demands.Furthermore, the 1450 Folder Gluer is equipped with state-of-the-art controls and automation systems, ensuring precise and consistent folding and gluing across each corrugated box. This level of precision not only enhances the overall aesthetics of the packaging but also contributes to the structural integrity of the boxes, providing added protection for the contents inside.In addition to its impressive performance, the 1450 Folder Gluer is also designed for versatility, capable of handling a wide range of box sizes and styles. This flexibility is invaluable for businesses that produce various types of big corrugated boxes, allowing them to streamline their production processes and reduce the need for multiple machines.Another key advantage of the 1450 Folder Gluer is its user-friendly interface and intuitive controls, making it easy for operators to set up and adjust the machine according to specific production requirements. This not only saves time but also minimizes the risk of errors, contributing to overall efficiency and cost savings for businesses.As with all {} products, the 1450 Folder Gluer is backed by the company's dedication to customer support and after-sales service. With a team of knowledgeable and experienced technicians, businesses can rely on {} for ongoing maintenance, technical assistance, and training to ensure optimal performance and longevity of their equipment.In conclusion, the introduction of the 1450 Folder Gluer for big corrugated boxes demonstrates {}'s continued commitment to delivering cutting-edge solutions that empower businesses to thrive in today's competitive market. With its revolutionary technology, speed, precision, and versatility, this machine is set to redefine the standards of packaging production, offering a competitive edge to those who invest in this innovative solution. For companies seeking to enhance their packaging capabilities, the 1450 Folder Gluer is undoubtedly a game-changer, propelling them towards greater efficiency and success in their operations.

New Breakthrough in the World of Automatic Screen Printing Machines Unveiled

Title: Advanced Automatic Screen Printing Machine Revolutionizes Printing IndustryIntroduction:The printing industry has seen numerous advancements over the years, with technological innovations continuously enhancing productivity and efficiency. One such breakthrough is the introduction of the revolutionary Automatic Screen Printing Machine by a leading player in the industry. This cutting-edge machine, which excels in performance and versatility, is set to redefine the standards of printing.Advanced Features of the Automatic Screen Printing Machine:The Automatic Screen Printing Machine offers a host of advanced features that make it an indispensable asset for businesses in the printing sector. With high-speed operation, exceptional print quality, and unrivaled flexibility, this machine is designed to meet the evolving needs of the industry.1. High-Speed Operation:Equipped with state-of-the-art technology, the Automatic Screen Printing Machine boasts an impressive speed, allowing it to quickly and efficiently produce large volumes of high-quality prints. Its superior performance ensures reduced lead times, enabling businesses to meet tight deadlines while maintaining optimal quality.2. Exceptional Print Quality:Precision is of utmost importance in the printing industry, and this machine delivers precise and consistent results every time. The Automatic Screen Printing Machine utilizes advanced color matching and registration systems, guaranteeing exceptional print quality regardless of the complexity or intricacy of the design. This ensures that the final product meets or exceeds customer expectations.3. Versatility:The versatility of the Automatic Screen Printing Machine sets it apart from its competitors. It can be easily adjusted to accommodate various printing substrates, including textiles, ceramics, plastics, glass, and many more. This flexibility allows businesses to explore diverse markets and cater to a wide range of customer requirements with a single machine.Company XYZ Drives Innovation:Leading the charge in printing technology, Company XYZ has brought forth the Automatic Screen Printing Machine, showcasing its commitment to revolutionizing the industry. With decades of experience and a customer-focused approach, Company XYZ has consistently developed and manufactured cutting-edge printing solutions for businesses worldwide.Established with a vision to deliver excellence, Company XYZ has earned a solid reputation for creating machines that redefine industry standards. They collaborate with industry experts to gather insights into market demands, allowing them to develop products that are not only innovative but also address the evolving needs of their customers.By leveraging their extensive research and development capabilities, Company XYZ has successfully incorporated the latest advancements in technology into the Automatic Screen Printing Machine. This dedication to innovation ensures that their machines remain at the forefront of the industry, providing businesses with a competitive edge.Conclusion:The introduction of the Automatic Screen Printing Machine marks a significant milestone in the printing industry. Its exceptional performance, high-speed operation, and versatility make it a game-changer for businesses seeking to enhance their printing capabilities. Company XYZ's commitment to innovation and customer satisfaction has paved the way for this groundbreaking technology, positioning them as a trailblazer in the industry.With the Automatic Screen Printing Machine, the future of printing has arrived, promising improved efficiency, reduced lead times, and top-notch print quality. Businesses that embrace this cutting-edge technology can expect to elevate their productivity and gain a competitive advantage in an ever-evolving market.

Enhance Packaging Efficiency with a High Capacity Folder Gluer for Large Corrugated Boxes

Introducing the Latest Advancement in Large-Scale Packaging: The 1450 Folder GluerIn the world of corrugated packaging, efficiency and precision play a crucial role in meeting the demands of modern manufacturing. To cater to the needs of large-scale box production, [Company Name], a leading player in the industry, has unveiled its most recent innovation - the 1450 Folder Gluer for big corrugated boxes. This revolutionary machine demonstrates the company's commitment to delivering cutting-edge solutions that streamline production processes and enhance productivity in the packaging sector.Featuring a state-of-the-art design and advanced technology, the 1450 Folder Gluer serves as a game-changer in the packaging industry. Its immense capability, coupled with the expertise of [Company Name], revolutionizes the way big corrugated boxes are manufactured, improving overall efficiency and significantly reducing production time.The 1450 Folder Gluer is specifically designed to cater to the unique demands of large-scale box production. With its impressive speed and accuracy, this machine ensures a seamless transition from raw materials to finished boxes. It integrates various functions, such as folding, gluing, and final quality control, into a single automated process. This integration eliminates the need for multiple machines, leading to a more compact production line and reducing the floor space required for manufacturing.One of the standout features of the 1450 Folder Gluer is its versatility. It can efficiently handle various types of corrugated boards, including single, double, and triple wall materials. Furthermore, it is capable of creating complex designs with precision, such as crash-lock bottom boxes, 4- and 6-corner boxes, and straight-line boxes, ensuring a wide range of packaging options for businesses. With its ability to cater to diverse packaging requirements, the 1450 Folder Gluer offers companies the flexibility to meet the demands of a rapidly evolving market.Safety and ease of use are key considerations in any manufacturing environment. The 1450 Folder Gluer incorporates multiple safety features to protect workers and minimize potential risks. Its ergonomic design enables operators to control and monitor the machine with ease, maximizing production efficiency while ensuring the well-being of the workforce.Furthermore, [Company Name] has prioritized sustainability in the development of the 1450 Folder Gluer. The machine includes features that optimize glue application, minimizing waste and reducing environmental impact. By promoting efficient use of resources, [Company Name] continues to pave the way toward a more environmentally conscious industry.The introduction of the 1450 Folder Gluer by [Company Name] has already received positive feedback from industry professionals. Manufacturers dealing with large-scale productions are particularly excited about the machine's capabilities, as it significantly reduces production time and costs while ensuring a high-quality end product.[Company Name] has established itself as a trusted partner in the global packaging industry. With a rich history of delivering state-of-the-art solutions, their commitment to innovation and customer satisfaction is evident in the 1450 Folder Gluer. By continuously pushing the boundaries of technology, [Company Name] aims to revolutionize large-scale packaging production, helping businesses worldwide enhance their operational efficiency and stay at the forefront of the ever-evolving packaging market.In conclusion, the launch of the 1450 Folder Gluer marks a significant milestone in the advancement of large-scale packaging. With its cutting-edge features, versatility, and commitment to sustainability, this innovative machine from [Company Name] sets new industry standards and cements the company's position as an industry leader. Embracing the 1450 Folder Gluer will empower businesses to meet the ever-growing demands of the modern packaging world, all while maintaining high levels of efficiency, productivity, and environmental responsibility.

Harnessing the Power of Film Surface Hot Press Lines for Effective Production

In the ever-expanding world of manufacturing, there are certain pieces of equipment that are essential for maintaining high production standards and manufacturing accuracy. One of these machines is the Film Surface Hot Press Line, a machine that is commonly used in the production of modern-day laminates. This machine is offered by several manufacturers, but one that stands out is {} which is known for its superior products and services.The Film Surface Hot Press Line is a machine that is designed to laminate a specific substrate with a decorative laminate sheet, creating a durable and visually appealing surface. The process is simple, yet effective, and involves the use of heat, pressure, and adhesive to bond the two materials together.The hot press line consists of several key components, including the loading and unloading station, the preheating station, the positioning system, the hot pressing station, and the cooling station. Each component plays a vital role in the successful operation of the hot press line.The loading and unloading station is where the operator loads the substrate and decorative laminate sheets onto the machine. The preheating station is used to warm up the materials, making them easier to handle in subsequent stations.The positioning system is where the operator precisely positions the substrate and laminate sheets to ensure that they are aligned correctly. The hot pressing station is where the actual bonding process takes place, as the substrate and laminate sheets are exposed to heat and pressure to create a seamless and durable surface. Finally, the cooling station is where the newly laminated product is cooled down to its final state.{} is one of the leading manufacturers of the Film Surface Hot Press Line, known for its innovative products and state-of-the-art technology. The company has been in the business of manufacturing laminating machines for over 20 years, and has built a reputation for excellence and quality.In addition to manufacturing high-quality machinery, {} also provides exceptional customer service and support. The company's team of experienced engineers and technicians are available to assist customers with any technical questions or issues that may arise.Furthermore, the {} hot press line is designed to be versatile and customizable, with several optional features that can be added to meet the specific needs of each customer. One of the key benefits of the machine is its ease of use, making it an ideal choice for both small-scale and large-scale laminating operations.Finally, it is notable that {} hot press line is designed with a focus on safety, incorporating several safety features to protect both the operator and the machine. These features include automatic shutdown in case of emergency and safety sensors to prevent accidents.In conclusion, the Film Surface Hot Press Line is an essential machine in the manufacturing of modern-day laminates, and {} is one of the leading manufacturers of this machine. With its innovative products, exceptional customer service, and commitment to safety, {} is a top choice for businesses looking for high-quality laminating machinery. Whether for small-scale or large-scale operations, the {} hot press line is a versatile and customizable machine that can meet the unique needs of any customer.

Discover the Benefits of a UV Coater Laminating Machine for High-Quality Finishes

Innovative Laminating Machine Enhances Printing Industry with UV Coating Technology[City Name], [Date] - In an increasingly competitive printing industry, the demand for high-quality and durable printing materials has been skyrocketing. In response to this growing need, [Company Name], a leading manufacturer of printing equipment, has launched its latest laminating machine type: the UV Coater. This state-of-the-art machine combines cutting-edge technology with the company's expertise to provide an enhanced printing experience for businesses worldwide.The [Company Name], widely renowned for its commitment to innovation, has once again taken a step forward with the introduction of the UV Coater. This game-changing machine offers a variety of features that set it apart in the market and cater to the multifaceted demands of the printing industry.One of the standout features of the UV Coater is its use of UV coating technology. Unlike traditional laminating machines, which typically use heat to bond the laminating film, the UV Coater utilizes ultraviolet light to cure the coating instantly. This not only results in a faster processing time but also allows for a more efficient and environmentally friendly operation. The absence of heat reduces energy consumption, eliminates the risk of volatile organic compounds (VOC) emissions, and eliminates the chances of paper curling or warping during the process.The UV Coater also boasts a superior coating quality, thanks to its advanced engineering. Equipped with high-definition micro-atomization technology, the machine ensures an even and precise coating distribution, leaving a flawless finish on various types of printed materials. From brochures and business cards to posters and packaging, the UV Coater guarantees a professional and eye-catching final product.Moreover, the UV Coater stands out due to its versatility. With adjustable settings, users can easily regulate the amount of coating applied, providing full control over the desired finish and ensuring compatibility with a wide range of materials. Additionally, the machine enables both spot coating and flood coating, allowing for creativity and customization in printing designs. This flexibility makes the UV Coater an ideal addition to printing businesses seeking to expand their offerings and stay ahead of the competition.Innovation and convenience go hand in hand with the UV Coater. The machine is equipped with an intuitive touchscreen panel, which simplifies the operation and allows for easy adjustments and monitoring of the coating process. Its user-friendly interface ensures that even those without technical expertise can operate the machine with ease, thereby reducing downtime and increasing overall productivity.The introduction of the UV Coater comes as [Company Name] continues to build on its reputation as a reliable and customer-oriented manufacturer. With a strong focus on research and development, the company constantly seeks to address the evolving needs of its customers. Furthermore, [Company Name] provides comprehensive customer support, ensuring that businesses can fully utilize the potential of their new UV Coater. From installation guidance to maintenance services, the company's dedicated team is committed to delivering unmatched assistance to their clients.The global printing industry is set to be revolutionized by the UV Coater, as businesses now have access to a cutting-edge solution that enhances the quality, durability, and efficiency of their printed materials. With its UV coating technology, impeccable results, and versatility, the UV Coater reaffirms [Company Name]'s commitment to providing first-class printing equipment that meets the demands of the modern market.About [Company Name]:[Company Name] is a trusted name in the printing industry, known for its innovative solutions and commitment to customer satisfaction. With decades of experience, the company has become a leading manufacturer of printing equipment, catering to businesses of all sizes and domains. [Company Name]'s dedication to research and development ensures that their clients receive top-notch machinery that enhances their printing capabilities.

Revolutionary New Folding Machine Unveiled, Set to Transform Industries

Title: Cutting-Edge Folding Technology Revolutionizes Industrial EfficiencySubtitle: [Company Name]'s Innovative Folding Machine Paves the Way for Manufacturing ExcellenceDate: [Insert Date][City, State] - [Company Name], a leading force in the manufacturing industry, has unveiled its groundbreaking folding machine, promising to transform industrial production lines and exponentially increase operational efficiency for businesses across various sectors. Combining ease-of-use with superior performance, this cutting-edge solution is set to revolutionize the way products are manufactured and packaged.With ever-increasing demands for fast and accurate folding operations, [Company Name]'s folding machine sets a new industry standard, significantly reducing production times while maintaining impeccable precision. Equipped with advanced automation features, this state-of-the-art equipment eliminates human error and delivers consistent high-quality folding results, boosting productivity and profitability.[Company Name], with its rich history of innovation and client-centric approach, understands the challenges that manufacturers face in today's competitive market. The introduction of this folding machine reflects the company's commitment to empowering businesses by providing practical and efficient solutions. Key Features and Benefits:1. Exceptional Precision: Built with cutting-edge technology, the folding machine ensures precise and accurate folding, eliminating even the slightest variations. This level of precision enhances product quality and reduces rejection rates, resulting in significant cost savings for manufacturers.2. Rapid Folding Speed: The machine's high-speed folding capabilities offer unmatched efficiency, enabling manufacturers to meet demanding production schedules with ease. With a remarkable folding speed and a quick setup process, businesses can streamline operations and achieve higher output volumes.3. Versatile Design: The folding machine's adaptable design enables it to handle a wide range of materials and product sizes, presenting a versatile solution for diverse manufacturing needs. This flexibility allows manufacturers to seamlessly transition between product lines without the need for extensive recalibration, enhancing overall production agility.4. User-Friendly Interface: [Company Name]'s focus on user experience is apparent in the folding machine's intuitive interface. With a user-friendly touch panel and simplified controls, operators can easily navigate and program the machine, minimizing training time and enhancing operational efficiency.5. Automated Adjustment: The machine's automated adjustment capabilities eliminate the need for manual intervention between production runs, further streamlining operations and reducing downtime. Once a specific folding pattern is programmed, the machine effortlessly adjusts all settings accordingly, allowing operators to focus on other crucial tasks.6. Space-Efficient Design: [Company Name]'s folding machine boasts a compact footprint, making it ideal for manufacturing facilities of all sizes. The space-efficient design optimizes factory floor space utilization and allows manufacturers to maximize output while minimizing overall footprint.The launch of this revolutionary folding machine has received widespread acclaim from industry experts and manufacturers alike. It is anticipated that this groundbreaking technology will redefine production and packaging processes across multiple industries, including textile, automotive, consumer electronics, pharmaceuticals, and more.As businesses continue to seek innovative solutions that optimize every aspect of their operations, [Company Name]'s folding machine positions itself as an indispensable tool that can accelerate production while ensuring consistently high-quality output. By minimizing human error, reducing lead times, and adapting to various manufacturing requirements, [Company Name]'s folding machine sets new benchmarks in efficiency, reliability, and productivity.[Company Name] continues to strive for excellence, constantly pushing the boundaries of innovation. Through their newest product, they reaffirm their commitment to helping manufacturers unlock their full potential, providing solutions that not only streamline operations but also lay the foundation for future growth and success.About [Company Name]:[Company Name] is a leading provider of cutting-edge manufacturing solutions, dedicated to delivering high-performance equipment tailored to meet the unique needs of businesses worldwide. With a focus on innovation, quality, and customer satisfaction, [Company Name] has established itself as a trusted partner in manufacturing excellence.For more information about [Company Name] and their revolutionary folding machine, please visit their website at [insert website].