Streamline Your Workflow with an Efficient Automatic Folder Machine

By:Admin

In today's fast-paced world, where time is of the essence, businesses across various industries are constantly searching for innovative technologies to streamline their processes and increase productivity. The garment industry is no exception, as manufacturers strive to meet the demands of an ever-growing market and deliver high-quality products in a timely manner. In this pursuit, a revolutionary machine has emerged, poised to transform the way garments are folded - the Automatic Folder Machine.

[Name of the company], a leading provider of cutting-edge technologies for the garment industry, has introduced its latest innovation, the Automatic Folder Machine. This state-of-the-art device combines intelligent design, advanced automation, and efficient folding mechanisms to revolutionize the folding process, offering unparalleled efficiency, accuracy, and speed to garment manufacturers.

The primary objective of the Automatic Folder Machine is to automate and expedite the labor-intensive task of folding garments. Traditionally, this process has required substantial human intervention, consuming a considerable amount of time and effort. Furthermore, manual folding can be prone to inconsistencies, leading to variations in the quality of the finished product. With the Automatic Folder Machine, these challenges become a thing of the past.

Equipped with cutting-edge technology, the Automatic Folder Machine streamlines the entire folding process. The machine utilizes state-of-the-art sensors, monitors, and algorithms to precisely identify the garment's dimensions, fabric weight, and texture. This information is then used to calibrate the machine, ensuring perfect folds every time, regardless of the garment type.

The Automatic Folder Machine combines this intelligent technology with an array of innovative mechanisms. The garments are fed into the machine through a conveyor belt, which transports them smoothly and consistently. As the garments enter the folding section, specially designed robotic arms gently and accurately fold them to the desired parameters. The machine can be programmed to accommodate various folding styles, including half-fold, quarter-fold, and custom folds, catering to the specific requirements of each garment.

One of the key advantages of the Automatic Folder Machine is its exceptional speed. With its automated processes, the device is capable of folding garments at an incredibly high rate, significantly surpassing the capabilities of manual labor. This increased efficiency allows manufacturers to meet stringent deadlines without compromising on quality, ensuring timely deliveries to their clients.

In addition to its time-saving capabilities, the Automatic Folder Machine also offers tremendous cost savings for garment manufacturers. The machine eliminates the need for a large workforce dedicated solely to folding garments, reducing labor costs significantly. Furthermore, the accuracy and consistency of the machine's folding mechanism minimize the occurrence of rejected or damaged garments, reducing material wastage and improving overall productivity.

The implementation of the Automatic Folder Machine has already garnered widespread attention and praise within the garment industry. Manufacturers who have adopted this cutting-edge technology have experienced remarkable improvements in efficiency, productivity, and customer satisfaction. The machine's ability to deliver perfectly folded garments consistently has earned it a reputation as a game-changer in the industry.

As the garment industry continues to evolve and adapt to changing market dynamics, technologies like the Automatic Folder Machine will become increasingly vital. With its unrivaled efficiency, precision, and cost-saving capabilities, this innovative solution has the potential to redefine the way garments are folded, setting new benchmarks in productivity, quality, and customer satisfaction.

[Name of the company] remains at the forefront of this technological revolution, continuously pushing boundaries to offer the latest advancements. As the Automatic Folder Machine gains momentum in the market, the garment industry can expect a paradigm shift in the way garments are processed, leading to a more efficient and competitive landscape for all stakeholders involved.

Company News & Blog

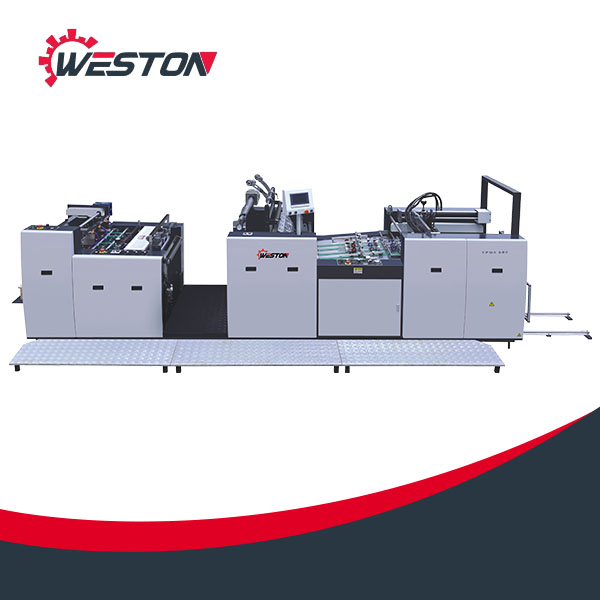

Advanced Model Auto Feeder Double Piece Folder Gluer Takes the Packaging Industry by Storm

Title: Advanced Auto Feeder & Folder Gluer Introduced by Industry LeaderIntroduction:In an era where automation and efficiency are paramount, technology continues to evolve across industries. __(Company Name)__, a renowned player in the packaging industry, has recently unveiled its revolutionary Heavy Model Auto Feeder Double Piece Folder Gluer. This advanced machinery has the potential to transform the manufacturing process, enabling businesses to meet increasing demands with enhanced productivity and precision.1. The Heavy Model Auto Feeder Double Piece Folder Gluer:The Heavy Model Auto Feeder Double Piece Folder Gluer (to remove brand name) is the latest addition to the impressive product lineup of __(Company Name)__. This robust machinery is designed to streamline the packaging process by combining automated feeding, folding, and gluing.a) Enhanced Feeding Mechanism:The auto feeder offers rapid and precise feeding capabilities, eliminating the risk of manual errors and saving precious time. It efficiently handles heavy stock, allowing for continuous production and reducing downtime. With adjustable settings and advanced sensors, the auto feeder can accommodate various carton sizes, making it highly versatile.b) Accurate Folding and Gluing:The double piece folder gluer integrates cutting-edge technology to ensure precise folding and seamless adhesive application. It eradicates intricate handwork by seamlessly folding cartons, reducing the chances of errors and maintaining consistency throughout the production cycle. The gluing mechanism ensures uniform and secure bonding, increasing the strength and longevity of the finished product.c) User-friendly Interface:The Heavy Model Auto Feeder Double Piece Folder Gluer incorporates a user-friendly interface, making it accessible to operators with various skill levels. The intuitive control panel allows for easy adjustments, minimizing setup time and operational complexity. Additionally, the machine's intelligent software provides real-time monitoring, error detection, and prompt error notifications, enabling swift intervention and preventing potential production delays.2. Impact on the Packaging Industry:a) Increased Efficiency:By automating the feeding, folding, and gluing processes, the Heavy Model Auto Feeder Double Piece Folder Gluer significantly enhances production efficiency. It reduces manual labor, human errors, and setup time, allowing manufacturers to meet tight deadlines and maximize output without compromising quality. The increased efficiency directly translates into improved profitability for businesses.b) Enhanced Product Quality:As the machinery ensures precise folding and uniform gluing, the finished products exhibit superior quality. The elimination of handwork reduces the risk of inconsistencies and errors, resulting in aesthetically pleasing cartons. Moreover, the robust gluing mechanism guarantees secure bonds, reducing the chances of product damage during transit.c) Versatility and Adaptability:The Heavy Model Auto Feeder Double Piece Folder Gluer caters to a wide range of carton sizes and designs, highlighting its versatility. It adapts effortlessly to the varying needs of different industries, such as food and beverage, pharmaceuticals, and consumer goods. This adaptability makes it a valuable asset for packaging businesses, thus broadening market opportunities.3. Company Profile:Established in __(year)__, __(Company Name)__ has been at the forefront of revolutionizing the packaging industry with its innovative products and cutting-edge technology. With a strong emphasis on research and development, the company continuously strives to provide comprehensive solutions to its global clientele. Through a network of distribution channels, it has garnered a reputation for delivering reliable machinery, impeccable customer service, and unparalleled technical support.Conclusion:The introduction of the Heavy Model Auto Feeder Double Piece Folder Gluer by __(Company Name)__ marks a significant milestone in the packaging industry. The advanced automation, accuracy, and versatility of this innovative machinery promise to revolutionize the manufacturing process, optimizing productivity and enhancing the quality of packaged goods. As industries continue to seek ways to stay ahead of the competition, automating key processes with advanced technology becomes essential, and __(Company Name)__ has successfully delivered a cutting-edge solution for packaging businesses worldwide.

Efficient UV Drying Tube Hot Stamping Machine Gains Favor for Drying and Stamping Needs

UV Drying Tube Hot Stamping Machine Revolutionizes Printing IndustryThe printing industry has always been at the forefront of technological advancements, constantly striving to improve efficiency and quality. One such innovation, the UV Drying Tube Hot Stamping Machine, is making waves in the industry with its ability to provide fast and high-quality printing results. This machine, developed by an industry-leading company, is revolutionizing the way printing is done, setting new standards for efficiency and productivity.The UV Drying Tube Hot Stamping Machine is designed to overcome the limitations of traditional drying methods used in the printing industry. Previously, printers had to rely on hot air or solvent-based drying systems, which were time-consuming and often resulted in inferior quality prints. However, with the introduction of the UV Drying Tube Hot Stamping Machine, printers can now achieve exceptional results in a fraction of the time.This groundbreaking machine utilizes advanced UV drying technology to rapidly dry prints, ensuring immediate curing and eliminating the need for additional drying time. Unlike other drying methods, UV drying leaves no residue, resulting in clean and vibrant prints. Moreover, the machine's hot stamping capability enables the addition of metallic and holographic effects, adding a touch of elegance and sophistication to any printed material.The company behind the UV Drying Tube Hot Stamping Machine is a renowned leader in the printing industry. With decades of experience and a commitment to innovation, the company has consistently delivered cutting-edge solutions to its customers. Their expertise and dedication to excellence have propelled the printing industry forward, and the UV Drying Tube Hot Stamping Machine is the latest testament to their success.Aside from its ability to provide exceptional printing results, the UV Drying Tube Hot Stamping Machine also offers several other advantages. Its compact design and user-friendly interface make it easy to operate and integrate into existing printing workflows. Furthermore, the machine's energy-efficient UV drying technology contributes to sustainable printing practices, reducing electricity consumption and minimizing environmental impact.The versatility of the UV Drying Tube Hot Stamping Machine is another standout feature. It can be used on a wide range of printing materials, including paper, cardboard, plastic, and even metal. This flexibility opens up new possibilities for printers, allowing them to cater to various industries and fulfill unique customer requirements. From packaging materials and labels to promotional items and security printing, this machine can handle it all with remarkable precision and speed.In addition to its performance capabilities, the UV Drying Tube Hot Stamping Machine also boasts a reliable and durable build. Its high-quality construction ensures longevity, minimizing downtime and maintenance costs for printers. This reliability, coupled with the company's renowned customer support, makes investing in this machine a wise choice for businesses looking to enhance their printing capabilities.With the introduction of the UV Drying Tube Hot Stamping Machine, the printing industry is ushering in a new era of efficiency and quality. This innovative machine, developed by the leading industry company, ensures fast and superb printing results, setting new benchmarks for productivity and customer satisfaction. Printers around the world can now benefit from the UV drying technology, streamlining their processes and delivering outstanding prints that captivate audiences. As the industry continues to evolve, the UV Drying Tube Hot Stamping Machine is undoubtedly a game-changer, revolutionizing the way printing is done.

Revolutionizing the Film Industry: Discover the Must-Have Dry Film Machine

Title: Cutting-Edge Dry Film Machine Revolutionizes Production ProcessIntroduction:In today's rapidly evolving manufacturing industry, technological advancements play a crucial role in enhancing productivity and efficiency. One such breakthrough comes in the form of a state-of-the-art Dry Film Machine, designed and developed by an innovative company. This groundbreaking equipment revolutionizes the production process, offering unparalleled accuracy and reliability. By combining cutting-edge technology with meticulous craftsmanship, the Dry Film Machine promises to transform industries and set new benchmarks for excellence.Section 1: Understanding the Dry Film MachineThe Dry Film Machine is a sophisticated device that specializes in applying dry film solder masks onto printed circuit boards (PCBs). This automated system streamlines the production process, reducing manual labor and ensuring impeccable quality control. By utilizing advanced robotics and precise digital controls, the Dry Film Machine provides consistent and uniform applications, resulting in optimally functional PCBs.Section 2: Features and Benefitsa) High Precision: The Dry Film Machine boasts exceptional precision, strategically positioning dry film solder masks onto PCBs with micron-level accuracy. This precision eliminates the risk of misalignments, improving overall performance and reliability.b) Increased Efficiency: Through its automated processes, the Dry Film Machine significantly reduces production time. With faster and more precise application capabilities, manufacturers can streamline their processes, swiftly meeting market demands.c) Cost-Effective: By reducing manual intervention in the solder mask application process, the Dry Film Machine curtails labor costs, while minimizing material waste and enhancing yield rates.d) Reliability: The Dry Film Machine guarantees uniform coverage, ensuring reliable, consistent performance of PCBs.Section 3: How It WorksThe Dry Film Machine utilizes advanced technologies to achieve optimal results. An integrated imaging system is equipped with high-resolution cameras, enabling precise alignment. Additionally, the machine's software analyzes and adjusts the application parameters based on the characteristics of each PCB, ensuring accurate and repeatable results.Section 4: Industry ApplicationsThe Dry Film Machine holds immense potential across various industries, including:a) Electronics Manufacturing: The production of intricate PCBs requires precise solder mask application, making the Dry Film Machine an indispensable asset for electronics manufacturers.b) Automotive: The automotive industry can leverage the Dry Film Machine to enhance the performance, durability, and longevity of PCBs used in vehicle electronics systems.c) Aerospace: The aerospace sector demands stringent quality control and maximum reliability. The Dry Film Machine facilitates the production of high-quality PCBs, meeting the industry’s exacting requirements.d) Telecommunications: The rapid growth of the telecommunications market necessitates efficient and reliable PCB production. The Dry Film Machine's ability to consistently deliver high-quality solder masks aligns perfectly with this sector's requirements.Section 5: Company Introduction{}, the innovators behind the Dry Film Machine, are renowned for their commitment to excellence and market-leading technology. With years of experience in developing advanced machinery, they continue to redefine industry standards. Committed to research and development, their team of skilled engineers and scientists prioritize customer satisfaction, delivering tailor-made solutions that meet specific industry needs.Conclusion:The Dry Film Machine revolutionizes the production process, elevating industry standards by ensuring precise, efficient, and reliable solder mask application. With its cutting-edge technology and unwavering commitment to excellence, it addresses the needs of various sectors, ranging from electronics manufacturing to aerospace. As we move towards a future shaped by automation and advanced manufacturing techniques, the Dry Film Machine stands as a testament to the possibilities that lie ahead, offering increased efficiency, enhanced productivity, and consistent quality.

Revolutionary Automatic Screen Printing Machine: A Game-Changer for the Industry

Automatic Screen Printing Machine Brings Efficiency and Precision to Printing IndustryIn the world of printing, precision and efficiency are the keys to success. Every print must be accurate, quick, and of high quality. However, achieving these goals can be challenging without the right equipment. This is where the Automatic Screen Printing Machine comes in. This innovative piece of machinery has revolutionized the printing industry and is now one of the most sought-after tools for printers across the globe.The Automatic Screen Printing Machine, which sources claim is one of the best ones in the market, is a state-of-the-art device that enables high-speed and high-precision printing. The machine uses a unique technology that ensures that each print is perfect, consistent, and of the highest quality. The technology is so advanced that it can print on various materials like paper, fabric, and plastic.One of the most impressive features of this technology is the fact that it is fully automatic. This means that it can work on its own, without any supervision from the operator. This is extremely beneficial for companies that need to print a large number of products within a short period of time. The Automatic Screen Printing Machine can work tirelessly for hours, ensuring that deadlines are met and clients’ expectations are exceeded.Moreover, the machine is incredibly versatile. It can be used to print on a wide range of products, including t-shirts, labels, banners, and even electronic devices. This means that companies that specialize in different types of printing can benefit from the machine’s capabilities. In addition, the machine is compact and easy to use, which makes it a great investment for small companies that are looking to expand their printing facilities.According to sources, the Automatic Screen Printing Machine is equipped with the latest technology that allows it to print with great precision. For example, the machine can adjust the pressure and angle of the print head, which ensures that the print is clear and uniform. Additionally, the machine can detect any errors in the printing process and correct them automatically. This eliminates the need for human intervention, which in turn reduces the chances of mistakes and enhances the overall quality of the print.The popularity of the Automatic Screen Printing Machine has grown steadily over the years. Many printing companies across the globe have invested in the machine to enhance their services and improve their competitiveness. The machine’s ability to print on various materials and its automatic nature have made it a valuable asset to these companies. Moreover, the machine has proven to be a cost-effective solution for many businesses, as it reduces the need for additional staff and equipment.One company that has benefited greatly from the Automatic Screen Printing Machine is {company name}. This company, which has been in the printing industry for over 20 years, specializes in printing t-shirts, hoodies, and other apparel items. Over the years, the company has built a strong reputation for delivering high-quality prints that meet customers’ expectations. However, as the company grew, it became apparent that it needed to invest in new equipment that could handle larger volumes of printing. This is where the Automatic Screen Printing Machine came in.According to {company name}’s CEO, John Doe, the Automatic Screen Printing Machine has been a game-changer for the company. “Before we invested in the machine, we had to rely on manual labor to handle large orders. This was not only time-consuming but also prone to errors. With the machine, we can now print hundreds of shirts in just a few hours, and the quality of the prints is unmatched. Our customers are very happy with the results.”The Automatic Screen Printing Machine has also enabled {company name} to expand its services and offer new products to its customers. “We can now print on various materials, such as nylon and polyester, which we couldn’t do before. This has allowed us to expand our product line and attract new customers. We are now able to offer a wider range of products at competitive prices thanks to the machine.”In conclusion, the Automatic Screen Printing Machine is a valuable asset to the printing industry, enabling companies to print efficiently and with precision. Its automatic nature, versatility, and advanced technology make it an essential tool for companies that want to expand their services and stay competitive. Companies like {company name} have successfully integrated the machine into their businesses, and it has become a valuable asset to them. With the continued advancement of technology and the demand for high-quality prints, it seems that the Automatic Screen Printing Machine will continue to play a significant role in the printing industry for years to come.

How to Choose the Best Screen Printing Machine for Your Business

Silk Screen Printing Machine Revolutionizes the Printing IndustryIn a world driven by technology and innovation, the printing industry has been no exception to the evolution. As demands for high quality and efficient printing continue to rise, companies are constantly looking for state-of-the-art machinery to meet their production needs. One such breakthrough technology that has taken the industry by storm is the Silk Screen Printing Machine.The Silk Screen Printing Machine, developed by a leading global manufacturer, has revolutionized the printing industry with its cutting-edge features and exceptional performance. This advanced piece of equipment boasts a range of functionalities that allow businesses to print vibrant designs on various materials, from fabrics and plastics to ceramics and metals.With its user-friendly interface and intuitive controls, the Silk Screen Printing Machine simplifies the printing process, allowing even inexperienced operators to achieve professional-grade results. The machine's precision and accuracy ensure that each print is flawless, meeting the highest industry standards. This not only saves time and resources but also enhances the overall quality and aesthetics of the printed products.One of the key features that sets the Silk Screen Printing Machine apart is its versatility. It can accommodate printing on a wide range of materials, making it an ideal choice for businesses in various industries, such as textiles, automotive, promotional products, and electronics. Whether it's creating intricate patterns on t-shirts or printing intricate designs on electronic circuit boards, this machine has the capability to handle it all.Furthermore, the Silk Screen Printing Machine offers unmatched speed and productivity, making it a preferred choice for companies with high-volume printing requirements. Its state-of-the-art technology ensures quick setup times, efficient production, and minimal downtime. This not only increases operational efficiency but also maximizes profitability for businesses.In addition to its impressive capabilities, the Silk Screen Printing Machine also prioritizes sustainability. It incorporates eco-friendly features that minimize energy consumption and reduce waste generation. By utilizing advanced printing techniques, companies can efficiently utilize resources and contribute to a greener future.The company behind this game-changing technology has been a pioneer in the printing industry for over two decades. With a strong focus on research and development, they have consistently introduced innovative solutions that have set new industry standards. As a global leader, their commitment to excellence is evident in the reliability and performance of their products.With an extensive distribution network spanning across the globe, the company has successfully catered to diverse customer needs. Their dedicated customer support team ensures that businesses receive unparalleled service and assistance throughout the entire printing process. From installation and training to ongoing maintenance and troubleshooting, the company is committed to delivering exceptional customer experiences.As the demand for high-quality printing continues to grow, the Silk Screen Printing Machine has become a game-changer in the industry. Its advanced features, versatility, and commitment to sustainability have made it the go-to choice for businesses worldwide. With innovative technologies like these, the printing industry is poised for a future of limitless possibilities.In conclusion, the Silk Screen Printing Machine, developed by a leading global manufacturer, has transformed the printing industry with its groundbreaking features and unparalleled performance. With its versatility, speed, and sustainability, this advanced technology is redefining the way businesses approach printing. As the industry continues to evolve, it is innovations like the Silk Screen Printing Machine that will shape its future.

Streamline Your Workflow with an Efficient Automatic Folder Machine

Introducing the Innovative Automatic Folder Machine: Revolutionizing Efficiency in the Garment IndustryIn today's fast-paced world, where time is of the essence, businesses across various industries are constantly searching for innovative technologies to streamline their processes and increase productivity. The garment industry is no exception, as manufacturers strive to meet the demands of an ever-growing market and deliver high-quality products in a timely manner. In this pursuit, a revolutionary machine has emerged, poised to transform the way garments are folded - the Automatic Folder Machine.[Name of the company], a leading provider of cutting-edge technologies for the garment industry, has introduced its latest innovation, the Automatic Folder Machine. This state-of-the-art device combines intelligent design, advanced automation, and efficient folding mechanisms to revolutionize the folding process, offering unparalleled efficiency, accuracy, and speed to garment manufacturers.The primary objective of the Automatic Folder Machine is to automate and expedite the labor-intensive task of folding garments. Traditionally, this process has required substantial human intervention, consuming a considerable amount of time and effort. Furthermore, manual folding can be prone to inconsistencies, leading to variations in the quality of the finished product. With the Automatic Folder Machine, these challenges become a thing of the past.Equipped with cutting-edge technology, the Automatic Folder Machine streamlines the entire folding process. The machine utilizes state-of-the-art sensors, monitors, and algorithms to precisely identify the garment's dimensions, fabric weight, and texture. This information is then used to calibrate the machine, ensuring perfect folds every time, regardless of the garment type.The Automatic Folder Machine combines this intelligent technology with an array of innovative mechanisms. The garments are fed into the machine through a conveyor belt, which transports them smoothly and consistently. As the garments enter the folding section, specially designed robotic arms gently and accurately fold them to the desired parameters. The machine can be programmed to accommodate various folding styles, including half-fold, quarter-fold, and custom folds, catering to the specific requirements of each garment.One of the key advantages of the Automatic Folder Machine is its exceptional speed. With its automated processes, the device is capable of folding garments at an incredibly high rate, significantly surpassing the capabilities of manual labor. This increased efficiency allows manufacturers to meet stringent deadlines without compromising on quality, ensuring timely deliveries to their clients.In addition to its time-saving capabilities, the Automatic Folder Machine also offers tremendous cost savings for garment manufacturers. The machine eliminates the need for a large workforce dedicated solely to folding garments, reducing labor costs significantly. Furthermore, the accuracy and consistency of the machine's folding mechanism minimize the occurrence of rejected or damaged garments, reducing material wastage and improving overall productivity.The implementation of the Automatic Folder Machine has already garnered widespread attention and praise within the garment industry. Manufacturers who have adopted this cutting-edge technology have experienced remarkable improvements in efficiency, productivity, and customer satisfaction. The machine's ability to deliver perfectly folded garments consistently has earned it a reputation as a game-changer in the industry.As the garment industry continues to evolve and adapt to changing market dynamics, technologies like the Automatic Folder Machine will become increasingly vital. With its unrivaled efficiency, precision, and cost-saving capabilities, this innovative solution has the potential to redefine the way garments are folded, setting new benchmarks in productivity, quality, and customer satisfaction.[Name of the company] remains at the forefront of this technological revolution, continuously pushing boundaries to offer the latest advancements. As the Automatic Folder Machine gains momentum in the market, the garment industry can expect a paradigm shift in the way garments are processed, leading to a more efficient and competitive landscape for all stakeholders involved.

Become a Master of Foil Stamping with this Manual Machine

Title: Revolutionary Foil Stamping Machine Revolutionizes Printing Industry Introduction:In a groundbreaking development, a leading company in the printing industry has unveiled an innovative Manual Foil Stamping Machine, set to revolutionize the way printing is done. This state-of-the-art machine is being hailed as a game-changer due to its cutting-edge technology, versatility, and unparalleled efficiency. With its ability to create stunning metallic foil finishes on a wide range of surfaces, this Manual Foil Stamping Machine is poised to transform the printing landscape.Expanding on the Company:The company behind this revolutionary Manual Foil Stamping Machine is a prominent industry leader recognized for its commitment to innovation and redefining printing techniques. Founded with the goal of constantly pushing boundaries, this company has consistently delivered top-of-the-line products and services to meet the evolving needs of the market.In aligning with their vision, the company's team of expert engineers and designers have developed this Manual Foil Stamping Machine to overcome the limitations of traditional printing methods. By leveraging advanced technology and an intuitive user interface, this machine provides a hassle-free and streamlined foiling process. Its ergonomic design ensures ease of use and maximum precision, allowing professionals and hobbyists alike to achieve stunning results effortlessly.Revolutionizing the Printing Landscape:The Manual Foil Stamping Machine is set to revolutionize the printing industry on multiple fronts. Its key features and benefits include:1. Unmatched Versatility: This cutting-edge machine is capable of stamping various surfaces, including paper, cardboard, plastic, leather, and so much more. Its adaptability opens up limitless possibilities for creative applications, making it an incredibly invaluable tool for designers and manufacturers across industries.2. Superior Foiling Precision: Harnessing the power of advanced technology, the Manual Foil Stamping Machine ensures impeccable foiling precision and accuracy. Regardless of the intricacy or complexity of the design, this machine guarantees flawless results, enhancing the overall aesthetic appeal of any print project.3. Time and Cost Efficiency: With its automated foil-feeding mechanism and rapid heat-up time, this machine significantly reduces the production time and material waste commonly associated with traditional foiling processes. It empowers businesses to meet tight deadlines while optimizing their resources, ultimately boosting productivity and profitability.4. Environmental Consciousness: The Manual Foil Stamping Machine incorporates energy-saving features without compromising on performance. Its eco-friendly design aligns with the growing global trend towards sustainable practices, making it an ideal choice for environmentally conscious businesses.Conclusion:With the introduction of the Manual Foil Stamping Machine, the printing industry experiences a seismic shift towards innovation, efficiency, and creativity. This cutting-edge technology, engineered by a leading industry player, simplifies and enhances the foiling process, providing unmatched versatility, precision, and time-cost efficiency. As businesses and individuals witness the immense transformative potential of this revolutionary machine, it is poised to become an indispensable tool for realizing stunning foiling effects across various applications.In a rapidly evolving world, the Manual Foil Stamping Machine undoubtedly paves the way for the future of printing, empowering professionals and enthusiasts to push boundaries and breathe life into their creative visions.

Harnessing the Power of Film Surface Hot Press Lines for Effective Production

In the ever-expanding world of manufacturing, there are certain pieces of equipment that are essential for maintaining high production standards and manufacturing accuracy. One of these machines is the Film Surface Hot Press Line, a machine that is commonly used in the production of modern-day laminates. This machine is offered by several manufacturers, but one that stands out is {} which is known for its superior products and services.The Film Surface Hot Press Line is a machine that is designed to laminate a specific substrate with a decorative laminate sheet, creating a durable and visually appealing surface. The process is simple, yet effective, and involves the use of heat, pressure, and adhesive to bond the two materials together.The hot press line consists of several key components, including the loading and unloading station, the preheating station, the positioning system, the hot pressing station, and the cooling station. Each component plays a vital role in the successful operation of the hot press line.The loading and unloading station is where the operator loads the substrate and decorative laminate sheets onto the machine. The preheating station is used to warm up the materials, making them easier to handle in subsequent stations.The positioning system is where the operator precisely positions the substrate and laminate sheets to ensure that they are aligned correctly. The hot pressing station is where the actual bonding process takes place, as the substrate and laminate sheets are exposed to heat and pressure to create a seamless and durable surface. Finally, the cooling station is where the newly laminated product is cooled down to its final state.{} is one of the leading manufacturers of the Film Surface Hot Press Line, known for its innovative products and state-of-the-art technology. The company has been in the business of manufacturing laminating machines for over 20 years, and has built a reputation for excellence and quality.In addition to manufacturing high-quality machinery, {} also provides exceptional customer service and support. The company's team of experienced engineers and technicians are available to assist customers with any technical questions or issues that may arise.Furthermore, the {} hot press line is designed to be versatile and customizable, with several optional features that can be added to meet the specific needs of each customer. One of the key benefits of the machine is its ease of use, making it an ideal choice for both small-scale and large-scale laminating operations.Finally, it is notable that {} hot press line is designed with a focus on safety, incorporating several safety features to protect both the operator and the machine. These features include automatic shutdown in case of emergency and safety sensors to prevent accidents.In conclusion, the Film Surface Hot Press Line is an essential machine in the manufacturing of modern-day laminates, and {} is one of the leading manufacturers of this machine. With its innovative products, exceptional customer service, and commitment to safety, {} is a top choice for businesses looking for high-quality laminating machinery. Whether for small-scale or large-scale operations, the {} hot press line is a versatile and customizable machine that can meet the unique needs of any customer.

Innovative Box Folding and Gluing Machine Enhances Packaging Efficiency

Carton Box Folder And Gluer Machine Revolutionizes Packaging IndustryThe packaging industry has undergone significant changes in recent years, with advancements in technology leading to more efficient and streamlined manufacturing processes. One such innovation that has transformed the sector is the Carton Box Folder And Gluer Machine (CGFM).This cutting-edge piece of equipment has revolutionized the way that cardboard packaging is manufactured, providing companies with a faster and more affordable solution for producing high-quality boxes of various shapes and sizes. With the CGFM, businesses can create customized packaging solutions that meet their unique requirements, whether they are small startup ventures or large conglomerates.The CGFM is designed to simplify the process of making cardboard boxes by automating many of the steps involved in the production process. It is capable of folding and gluing both straight and angled boxes, enabling manufacturers to produce different types of boxes with a higher level of precision.Apart from offering a quick and efficient way to manufacture cardboard packaging, the CGFM also helps businesses reduce their environmental footprint. As an eco-friendly alternative to traditional packaging materials, cardboard is a recyclable and biodegradable material that can be used to create a wide range of products.The need for sustainable packaging solutions has become more critical than ever, with businesses around the world taking steps to minimize their environmental impact. With the use of the CGFM, businesses can create cardboard boxes that are not only customizable but also more environmentally friendly.Leading provider of CGFM machines globally, the company has gained a reputation for its expertise and commitment to innovation. As a company that focuses on delivering high-quality products and excellent customer service, they have earned the trust and loyalty of many businesses around the world.Through their extensive research and development efforts, the company has been able to produce a CGFM machine that is reliable, efficient, and durable. They are also committed to ongoing product development and are continuously looking for ways to improve their products and services.In addition to providing top-of-the-line equipment, the company also offers training and support services to their customers. This ensures that their clients are equipped with the knowledge and skills needed to operate and maintain the CGFM machines effectively, thus maximizing their investment in this innovative technology.The CGFM machine has become increasingly popular among businesses globally, with its use providing a range of benefits. The machines come in different models, each designed with specific features that fit the various needs of different businesses. Regardless of the size of the enterprise, the CGFM machine provides an optimal packaging solution that delivers on affordability, precision, and sustainability.One notable advantage of investing in the CGFM is that it enables businesses to cut down on labor costs by reducing the number of human resources required for packaging production. The machine's automation capabilities eliminate the need for costly manual labor, ultimately boosting productivity and increasing profits.Another key benefit is that the machine produces higher quality products, thanks to its accuracy and precision. The CGFM ensures that boxes are made with the exact specifications required, reducing the likelihood of defects and returns.Overall, the CGFM has become an invaluable tool in the packaging industry, providing companies with a competitive edge by offering them a cost-effective and sustainable packaging solution. With the ever-increasing demand for customizable and eco-friendly packaging solutions, the CGFM continues to lead the way in revolutionizing the packaging industry.